1 Introduction

Aluminum alloy drill pipes are widely used for their lightweight and high specific strength [1-4]. However, the poor wear resistance and corrosion resistance seriously affect its safety and reliability in the application [5-8]. Aluminum matrix composites (AMCs) have been widely used in aircraft, automobiles, and electronics [9, 10]. Not only having great specific strength, AMCs also have desirable wear resistance, fatigue resistance, chemical stability, and processing performance [11-14]. Therefore, the study of AMCs for drill pipes is of great meaning.

Basalt fiber is prepared from natural basalt, which has good chemical stability, corrosion resistance, and high temperature resistance, and is often used as an important material for composite reinforcement [15-18]. MARINI et al [19] have studied the short basalt fiber/AZ63 magnesium alloy composites, basalt fibers have good impregnation and strong interfacial interaction with the magnesium alloy matrix. The application of basalt fibers in aluminum alloys has also received the attention of many scholars [20]. EZHIL VANNAN et al [21] prepared short basalt fiber reinforced AMCs by composite casting process and studied their dry sliding wear behavior, the wear resistance of basalt short fiber composites is superior to that of matrix alloy. ADOLE et al [22] prepared basalt fiber/A356 AMCs by stirring casting technique and found the intermetallic compounds in the matrix-fiber interface improved the tensile strength and wear resistance of the composites. BRUCE RALPHIN ROSE et al [23] prepared basalt fiber/7075 AMCs for automotive clutches by stir casting, the friction and wear characteristics of the composites were experimentally investigated using a pin-on-disk apparatus, and justified the application of basalt fibers in clutch facings. KARTHIGEYAN et al [24] prepared Al/basalt short fiber metal matrix composites by the permanent stir casting technique, and found that forging can improve the fatigue strength of composites. Existing studies have shown that it is feasible and has practical significance to add basalt fibers to 7075 aluminum alloys to enhance the performance of aluminum alloys. The application of basalt fiber reinforced composites in aluminum alloy drill pipes is also of research significance. However, the mechanical properties and wear behavior of the composites when applied to drill pipes still need to be further investigated.

While reading the above literatures, we noticed that the addition of basalt fibers in these studies was generally chosen between 0 and 10 wt.%. However, in our previous study, we found that adding a small amount of basalt fibers (0.2 wt.%, 1.0 wt.%) resulted in a significant enhancement of the corrosion resistance of 7075 AMCs prepared by hot-press sintering. Basalt fibers can react with the aluminum matrix and form an Al2O3 interfacial reaction layer, effectively improving the corrosion resistance of AMCs [25]. However, when we discuss the application of basalt fibers/7075 AMCs in drill pipes, the strength and wear resistance of the AMCs are equally crucial with their corrosion resistance. In order to more comprehensively study the feasibility of basalt fibers/7075 AMCs applied to aluminum alloy drill pipes, we further investigated the mechanical properties and wear behaviors of the AMCs on the basis of previous studies.

In this paper, the AMCs with different basalt fiber additions were prepared by hot pressed sintering and hot extruded. Microstructure analysis, mechanical property tests, and friction wear experiments were carried out. It is worth mentioning that we investigated the uneven wear on the ED-TD surface of extruded AMCs after the wear experiment and discussed its effect on wear resistance.

2 Experimental materials and methods

AMCs with basalt fiber additions of 0 wt.%, 0.2 wt.%, 0.6 wt.%, 1.0 wt.% and 2.0 wt.% were prepared and named 7075 and 7075-xBF (x=0.2, 0.6, 1.0 and 2.0). The selected basalt fibers were produced by Jilin Tongxin Basalt Technology Co., Ltd., with an average monofilament diameter of 13 μm. Short basalt fibers were prepared from long fibers by shearing, ball milling, and sieving. The selected 7075 aluminum powder was produced by Shanghai Chaowei Nano Technology Co., Ltd., with a purity of 99.9% and an average size of 5 μm. The compositions of basalt fibers and 7075 aluminum powder are shown in Table 1.

| Sample | SiO2 | Al2O3 | TFe2O3 | CaO |

|---|---|---|---|---|

| Basalt fiber | 51.22 | 16.92 | 9.03 | 9.77 |

| Sample | MgO | K2O | Na2O | TiO2 |

| Basalt fiber | 7.2 | 1.85 | 2.04 | 1.75 |

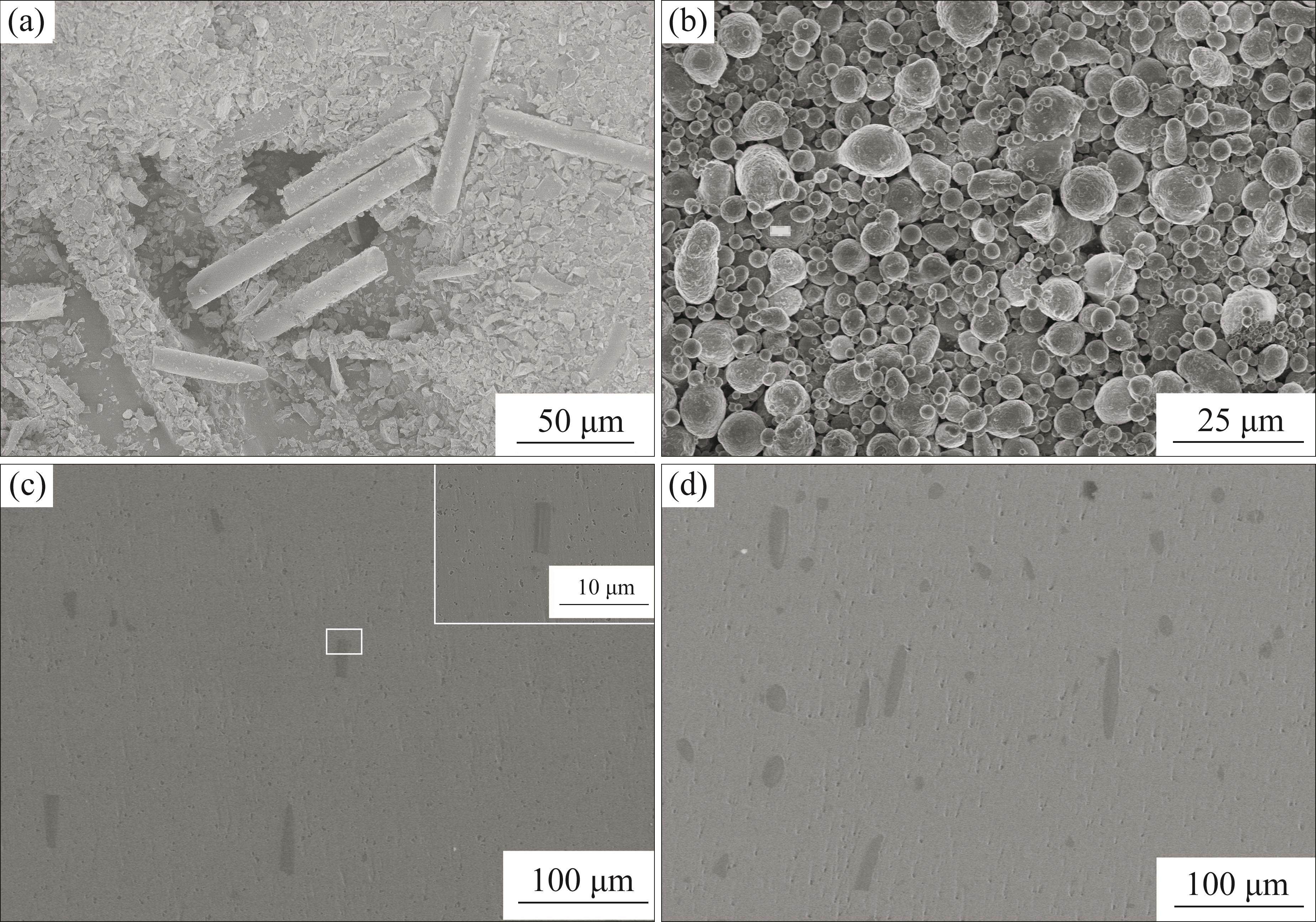

In a previously published research article [25], we described in detail the preparation of basalt fiber-reinforced 7075 AMCs by hot pressed sintering. Basalt fibers and 7075 aluminum alloy powder were first placed in anhydrous ethanol for ultrasonic dispersion and electromagnetic stirring. Afterward, highly homogeneous mixed powders were obtained by filtration, drying, and ball milling. Finally, AMCs were prepared by hot pressing sintering (580 ℃, 30 MPa, 15 min). The extrusion treatment of the AMCs was carried out after a homogenizing heat treatment lasting for 4 h at 470 ℃, with an extrusion pressure of 40 t, a temperature of 470 ℃, and an extrusion ratio of 12:1. Figure 1 shows the SEM observations of basalt fibers, 7075 aluminum alloy powder, and AMCs with basalt fiber content of 0.6 wt.%, and 2.0 wt.%.

The microhardness was tested by HXD- 1000TM/LCD digital microhardness tester. The size of the sample was 10 mm×10 mm×5 mm, and it was polished with 2000 grit sandpapers and ultrasonically cleaned with alcohol for 10 min to ensure that the surface of the samples was smooth and flat. The measurement load was 100 g, and the dwell time was 15 s. In order to ensure the accuracy of the test results, each sample was measured 5 times at least.

The tensile tests were carried out on a DDL- 100 electronic universal testing machine. The tensile samples with a gauge length of 10 mm were cut out by wire electric discharge machine. The tensile rate was 0.6 mm/min. All samples were polished with 2000-grit sandpaper and ultrasonically cleaned with alcohol. The test was repeated three times for each group of samples.

The friction wear test was carried out by the UMT-2 friction testing machine. The carbon steel friction ball was used as the friction partner. The diameter of the circumferential wear was 2 mm, the rate was 200 r/min, and the applied load was 15 N. The duration of the friction and wear test was 20 min. After the friction wear experiments, the wear of the samples was analyzed using a three-dimensional surface profiler (Phase Shift Micro XAM-3D). Confocal laser scanning microscope (CLSM) and scanning electron microscope (SEM) were used to observe the wear morphology.

3 Result and discussion

3.1 Microstructure

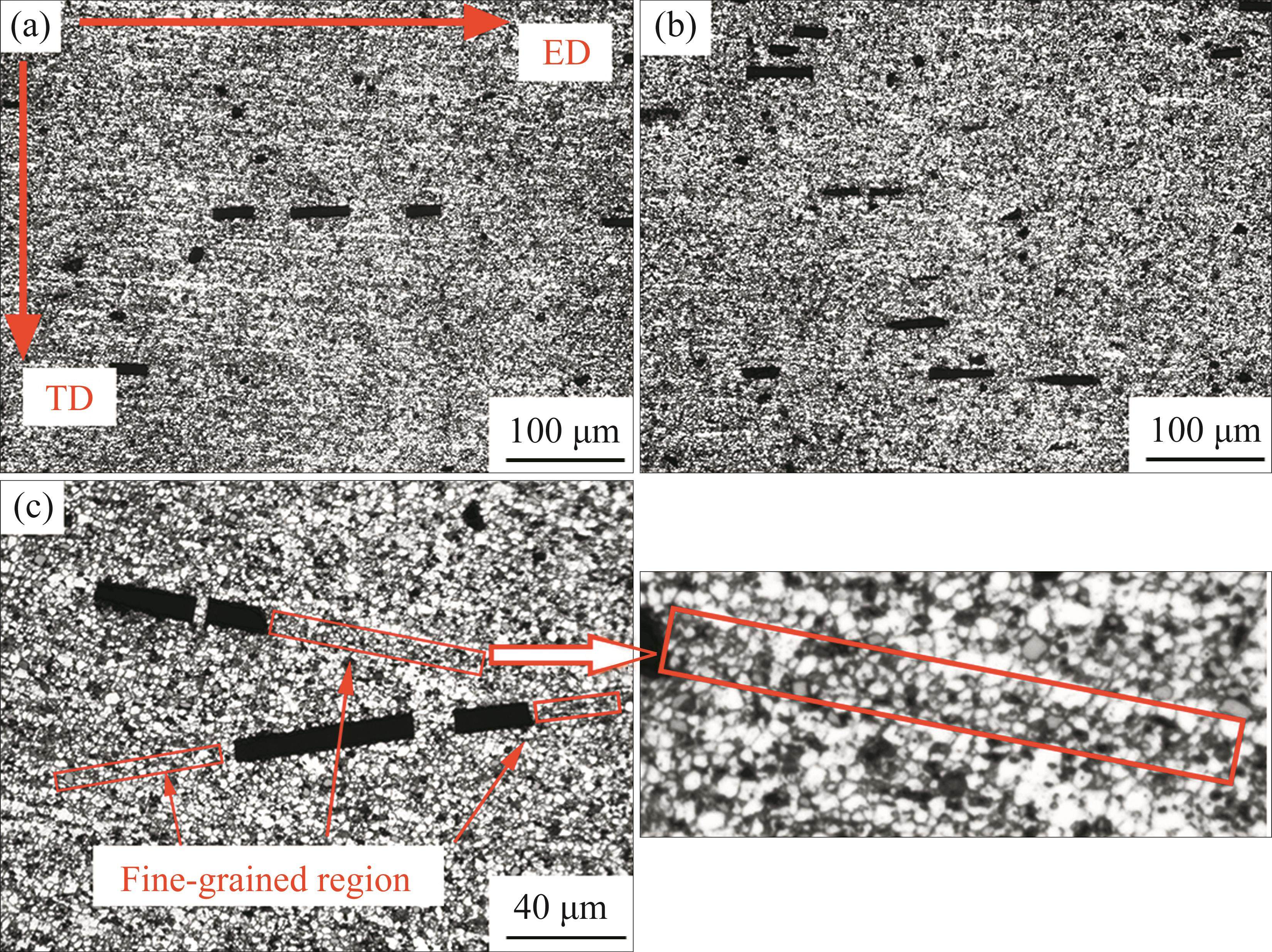

Figure 2 shows the metallographic corrosion morphology of the composites. After hot extrusion, the basalt fibers show directional arrangement in the alloy matrix along the extrusion direction during high-temperature rheology, as shown in Figures 2(a) and (b). It is noteworthy that there is a band-shaped fine-grained region at the fiber end along the fiber extension direction, as shown in Figure 2(c).

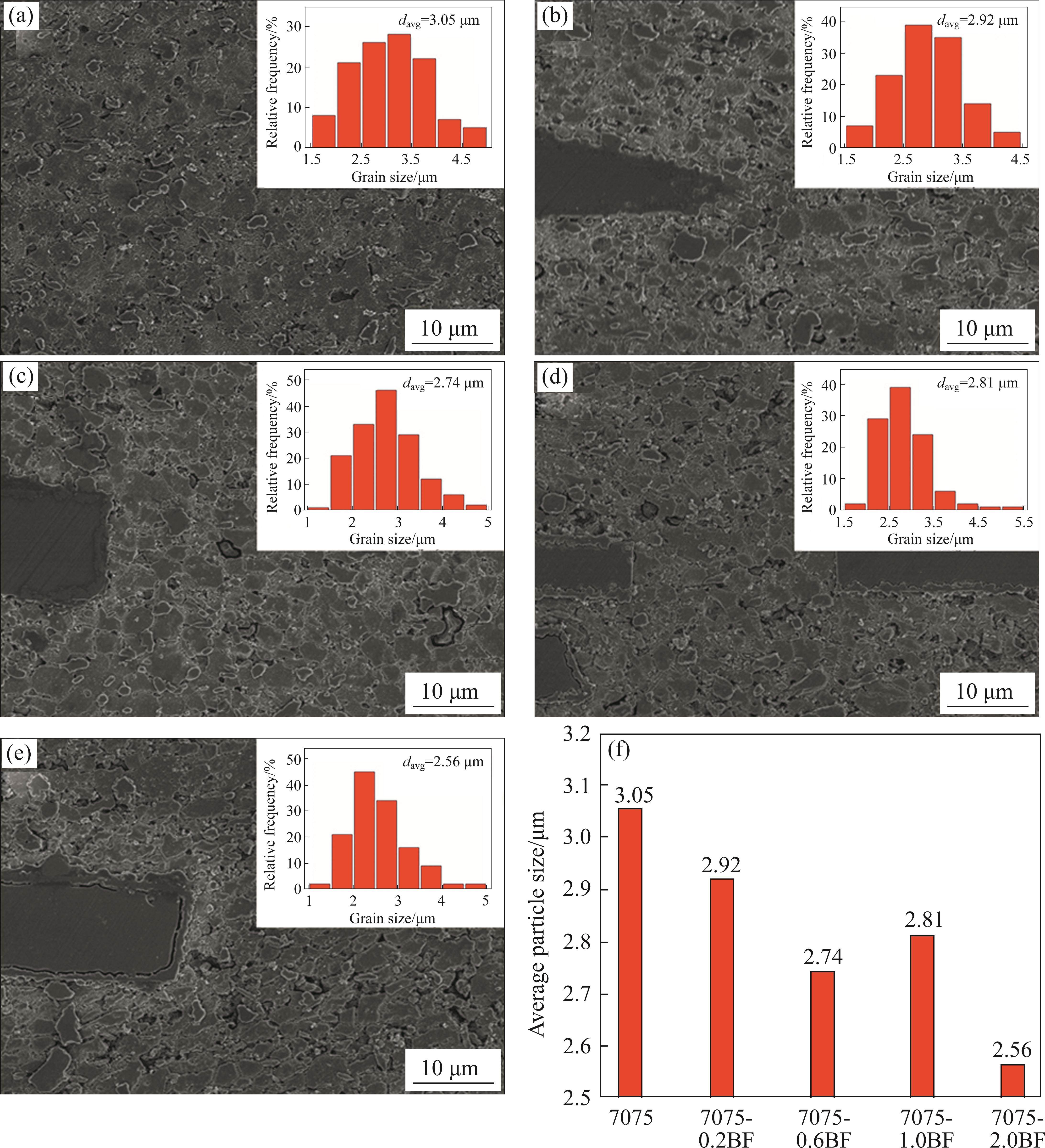

During the hot extrusion process, a certain stress field was generated by the rheological resistance of the fibers, which extruded and broke the surrounding crystal structure and generated the effect of grain refinement. The size of the grains around the fibers was counted by Nano Measure 2.1 software, as shown in Figure 3. The average grain size of the AMCs gradually decreased with increasing basalt fiber content, except for 7075-1.0BF. The hardness and wear resistance of AMCs can be enhanced due to the strengthening effect of grain refinement [26].

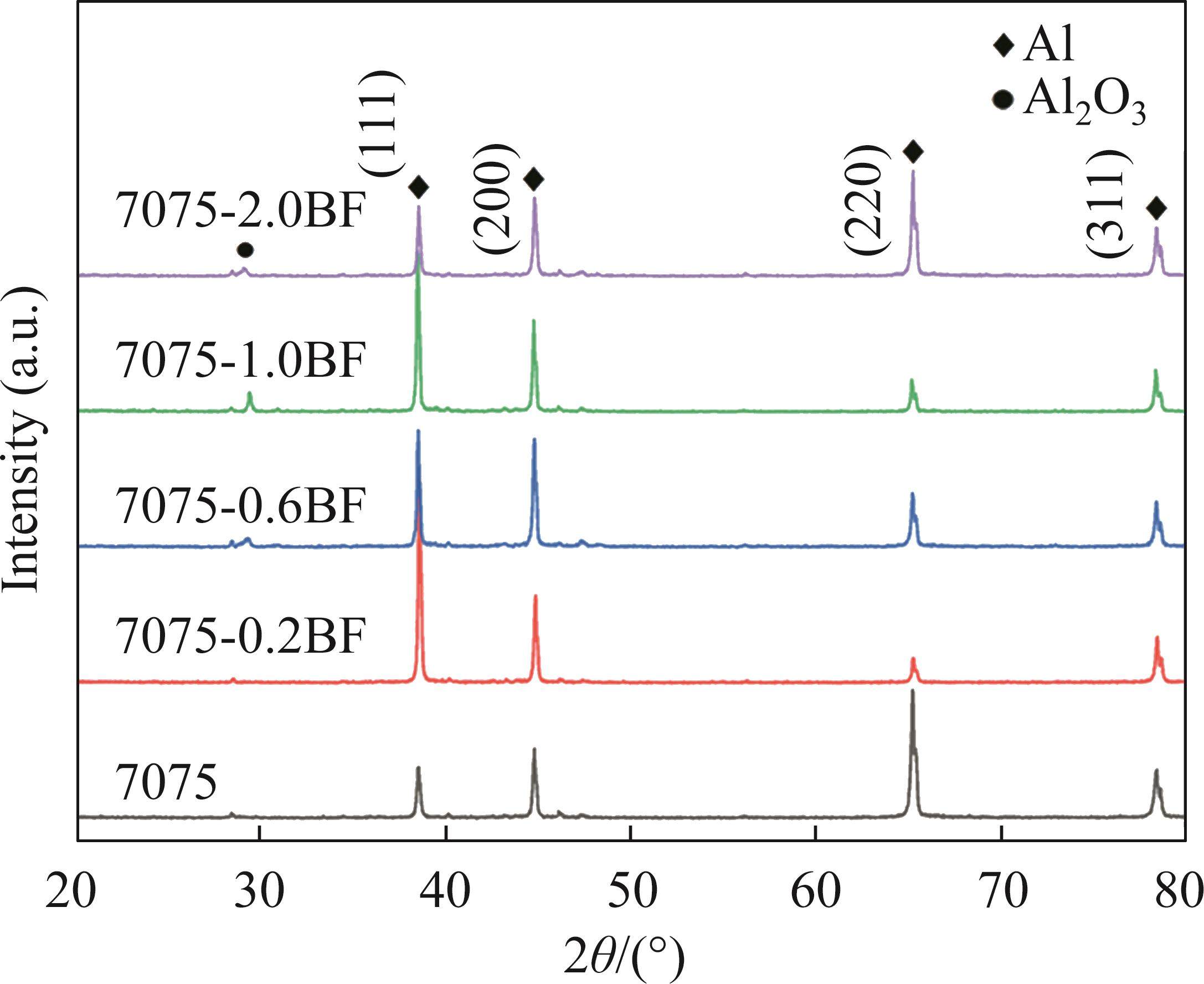

Figure 4 shows the XRD patterns of AMCs with different fiber contents. Four diffraction peaks of Al were observed in all spectral lines, which were the (111) Al diffraction peak with a diffraction angle of 38.4°, the (200) Al with 44.8°, the (220) Al with 65.1°, and the (311) Al with 78.3° (PDF#65-2869). There is no marked change at the four diffraction peaks of Al in each spectral line, indicating that the content of basalt fibers has no significant effect on the orientation of Al crystals. After adding basalt fiber, the Al2O3 diffraction peak with a diffraction angle of 29.1° (PDF#52-0803) was observed, and the peak of Al2O3 diffraction peak was enhanced with the increase of basalt fiber content. The Al2O3 in the sample came from the Al2O3 reaction layer produced by the interfacial reaction between the fiber and the matrix.

3.2 Mechanical properties

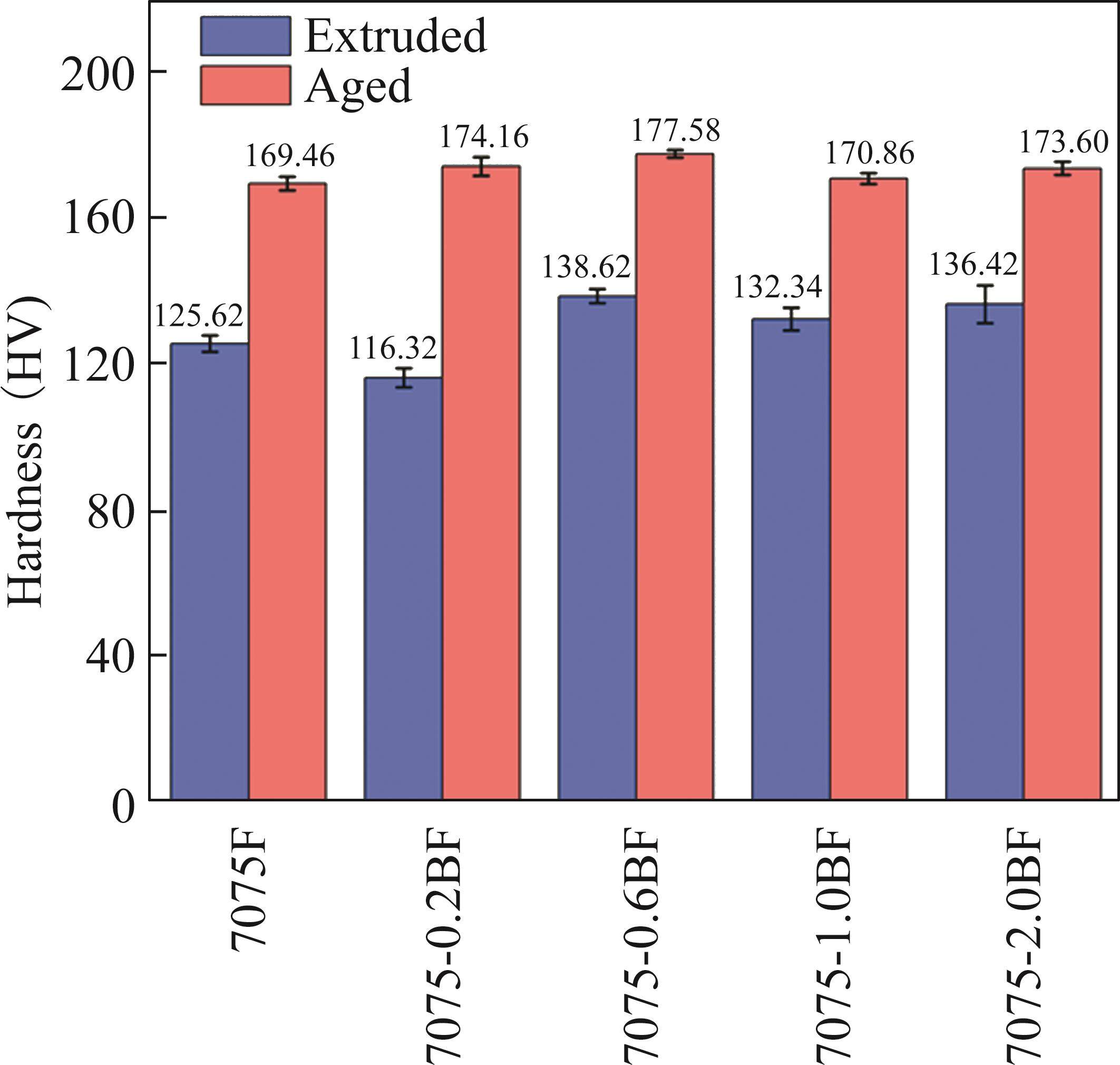

As an alloy that can be strengthened by heat treatment, 7075 aluminum alloy is often heat-treated to improve malleability, strength and hardness [27]. Therefore, we have also investigated the effect of basalt fiber addition on the hardness of 7075-T6 aluminum alloy. Some of the hardness test samples were subjected to T6 heat treatment (solid solution treatment at 550 ℃ for 1 h and aging treatment at 120 ℃ for 24 h).

Figure 5 shows the microhardness test results of AMCs with different basalt fiber additions. 7075-0.6BF has the highest hardness of HV 138.6 compared with other extruded samples, which is about 9.5% higher than 7075. On the one hand, basalt fibers have higher hardness than 7075. On the other hand, the fibers can refine the grains, resulting in the increase of grain boundaries, which can hinder the movement of dislocations. AMCs with the addition of basalt fibers show stronger resistance to indentation and improved hardness.

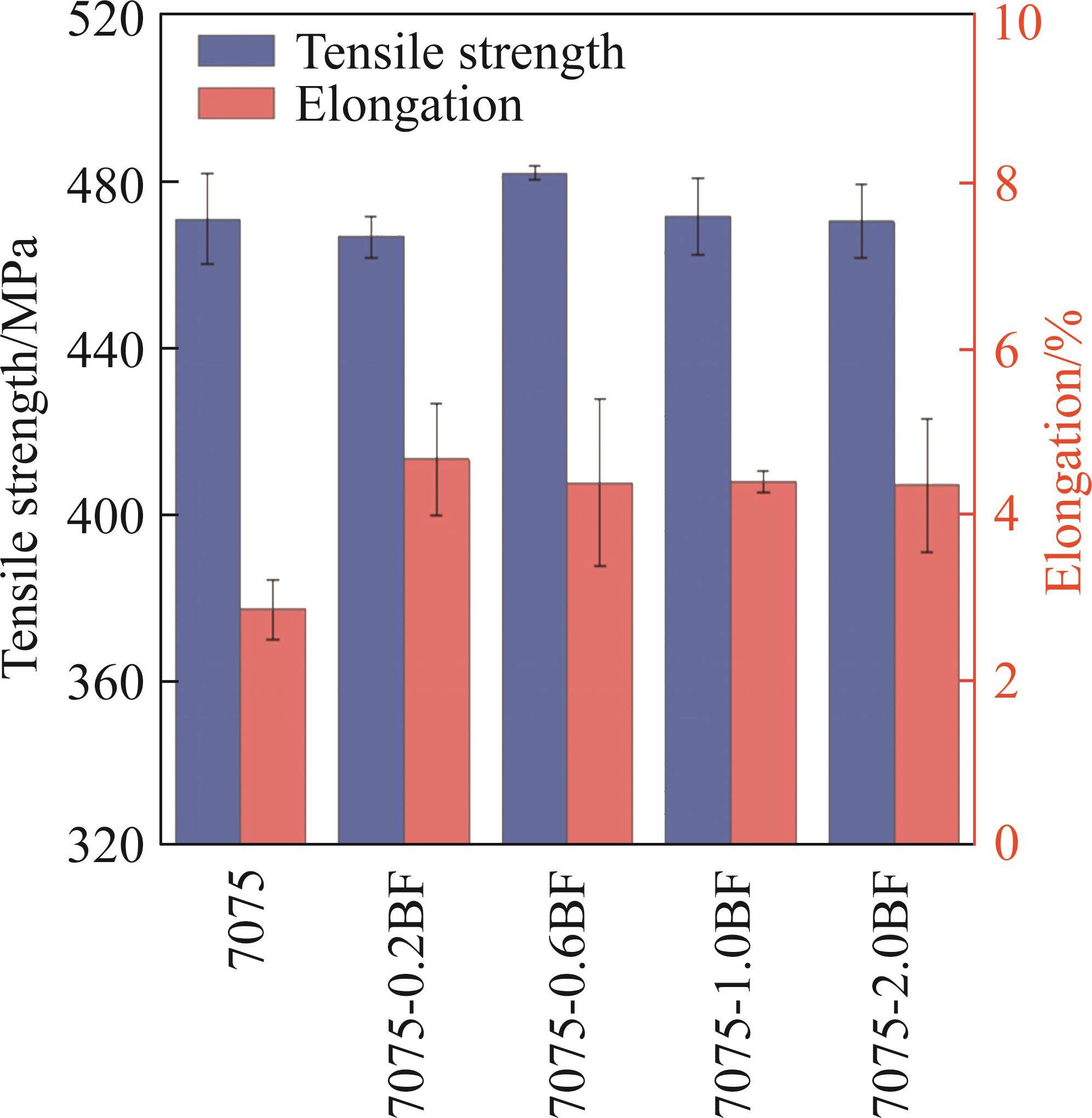

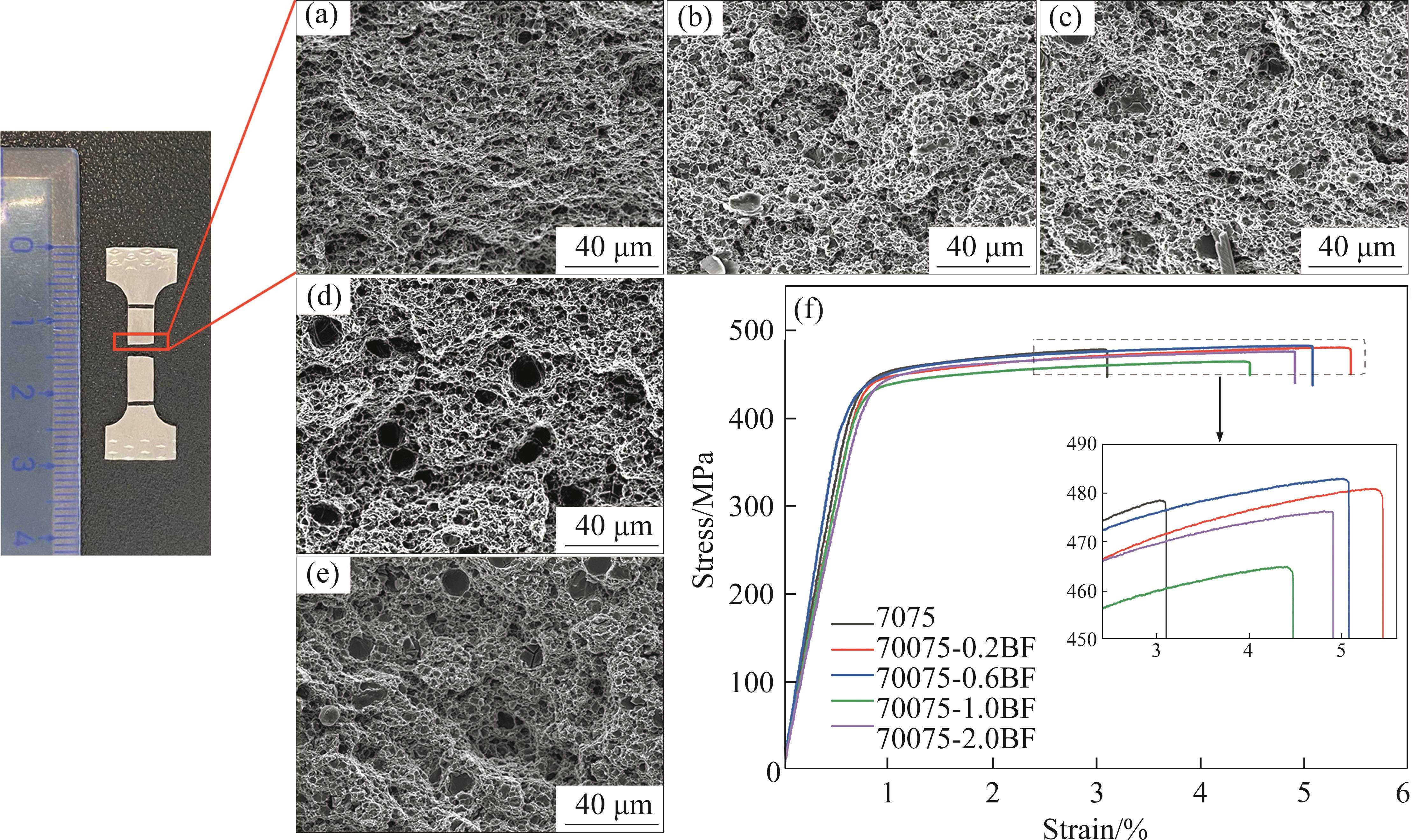

Figure 6 shows that the tensile strength of the AMCs is almost unaffected by the addition of basalt fibers, but the elongation is significantly improved. Figures 7(a)-(e) show the fracture morphology of AMCs after stretching and Figure 7(f) shows the stress-strain curve. The AMCs have undergone an elastic deformation phase and a plastic deformation phase during tension. In Figures 7(a)-(e), toughness nests appear in the fracture of all samples. The fracture surface of the 7075 without fibers was smoother. The fracture surfaces of the composites with the addition of basalt fibers had greater undulations and smaller, denser dimples, indicating greater fracture toughness. Figures 7(b)-(e) show that most basalt fibers suffer shear damage. Crack extension occurs within the fibers and extends to the fiber surface, but does not extend further into the alloy matrix. From Figures 7(a)-(e), the morphological undulation of the composite tensile fracture becomes greater with the increase of basalt fiber content, and there are fine toughness nests around the fibers.

Fracture of fiber-reinforced composites is usually classified into three failure modes: fiber pullout, fiber and matrix separation, and fiber shear failure [28-30]. Normally, when fibers have appropriate interfacial bond strength with the matrix, they can effectively transfer and bear loads. However, the strong interfacial bond between the fibers and the matrix results in the fibers being more susceptible to shear damage due to stress concentrations.

As mentioned above, basalt fibers can refine the grain and form a chemically reactive layer with the alloy matrix at the interface. The fibers are well bonded to the matrix and are able to transfer and carry loads efficiently when subjected to tension. However, basalt fibers are prone to shear damage due to stress concentration. Basalt fibers cause fine grain zones surrounding the fibers in the alloy matrix, resulting in an increase in grain boundaries that can effectively impede dislocation expansion and thus improve the strength and toughness. But the increased addition of basalt fibers affects the continuity of the matrix. As a result, the AMCs exhibit better ductility than 7075, but the tensile strength fails to be significantly improved.

3.3 Friction and wear

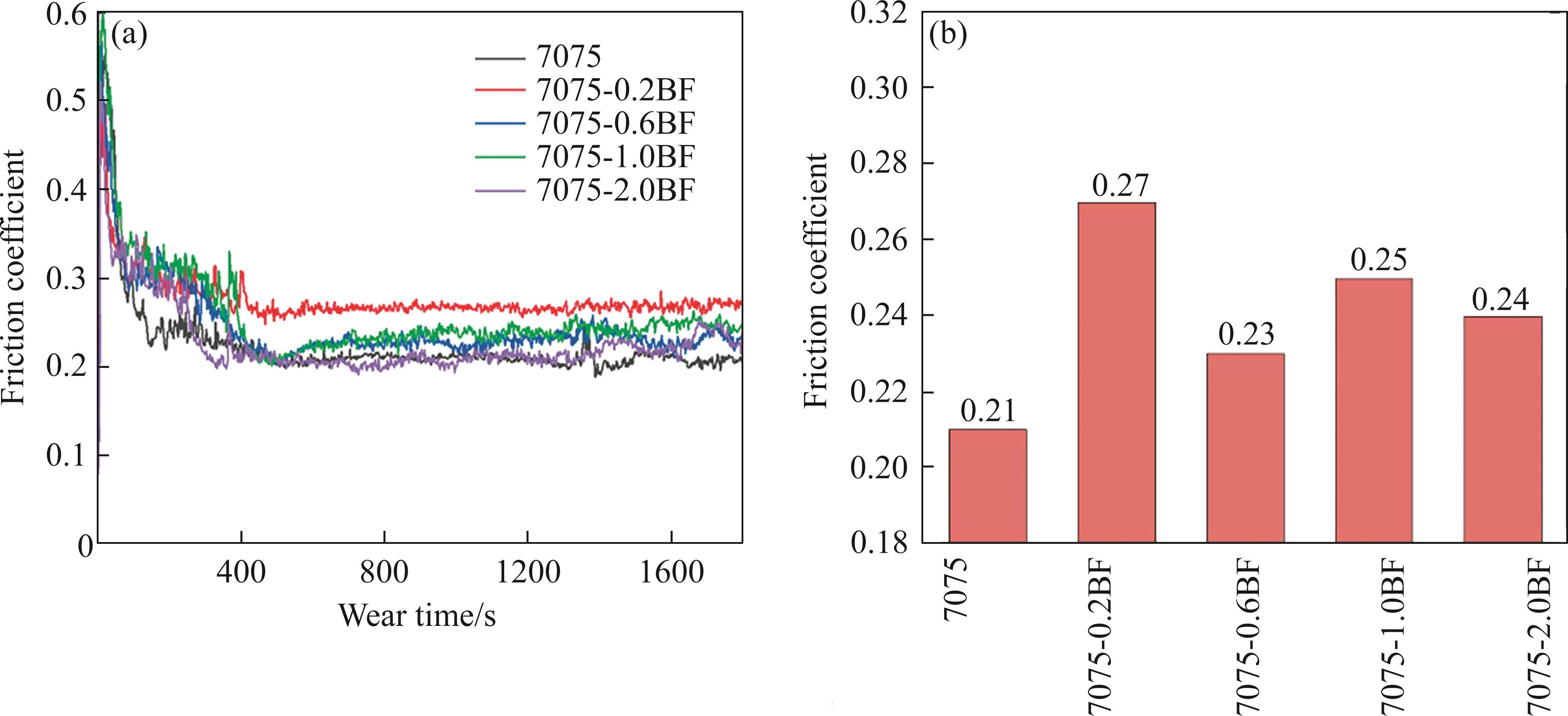

Figure 8(a) shows the curves of friction coefficient with time for AMCs with different basalt fiber addition. The friction coefficient of the AMCs increases and then decreases with the increased basalt fiber content, as shown in Figure 8(b). The physical meaning of the friction coefficient is the probability that a certain point of the sample is subjected to force during the friction process to generate abrasive particles [31, 32]. The friction coefficient could quantitatively analyze the possibility of the sample matrix peeling off and producing abrasive particles during the wear process. The larger the friction coefficient, the easier it is to peel off to form abrasive particles. However, the value of the friction coefficient cannot fully represent the wear resistance. The wear depth, mass loss and wear morphology of AMCs after friction experiments provide a more accurate response to the wear resistance.

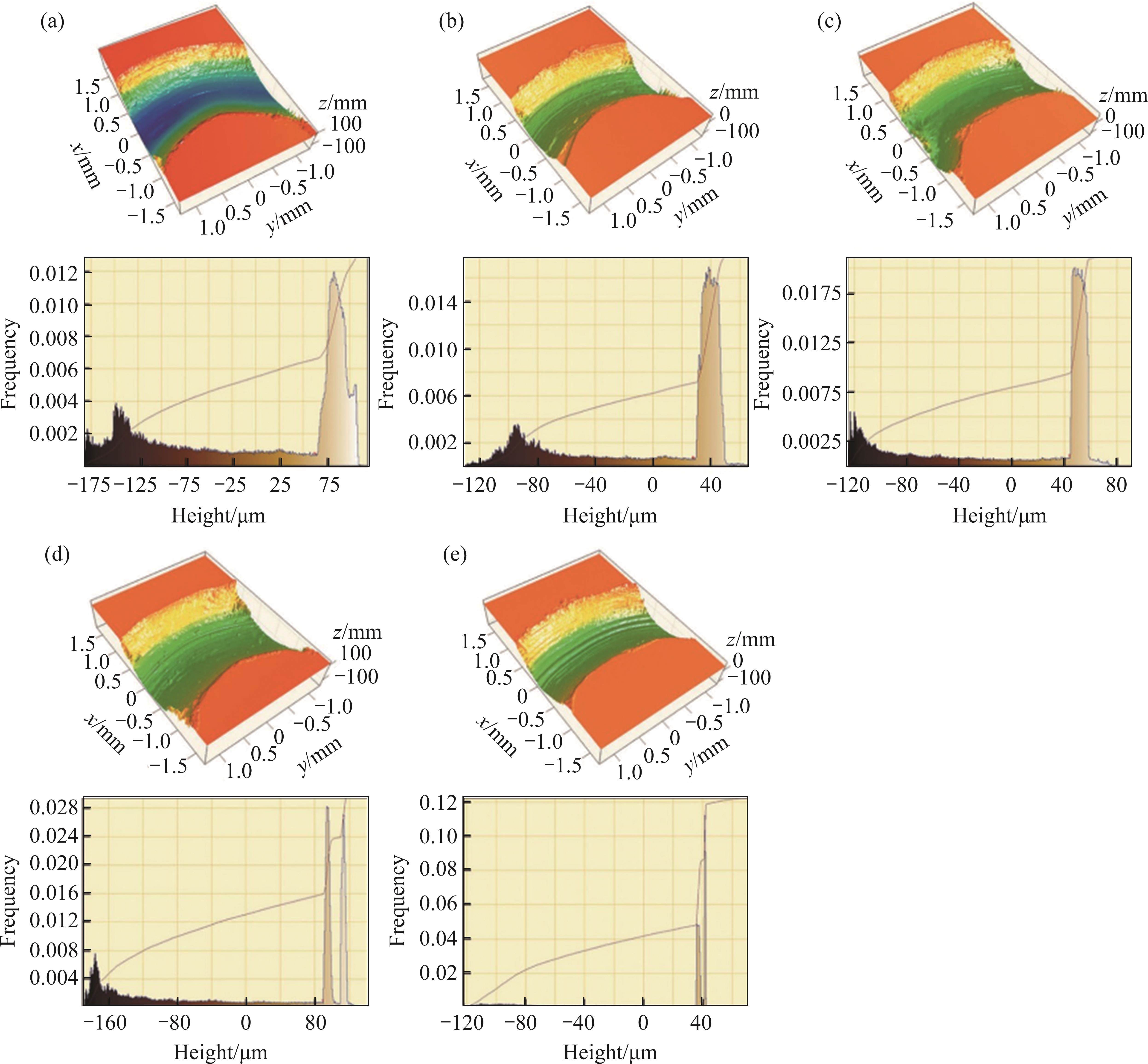

Figure 9 shows the three-dimensional wear patterns of the AMCs after testing. The wear depth of the samples after testing was measured using a laser scanning confocal microscope, and the maximum wear depth was recorded. In addition, the mass loss of the samples after wear was recorded, as shown in Table 2. The maximum wear depth and wear volume of the AMCs are less than those of 7075 aluminum alloy, except for 7075-1.0BF. 7075-2.0BF has the weakest wear, the smallest maximum wear depth, and the smallest mass loss. The wear volumes of 7075-2.0BF and 7075-0.2BF are close to each other and only about 50% of the wear volume of 7075.

| Alloy | Maximum wear depth/μm | Wear volume/mm3 | Relative mass loss/mg |

|---|---|---|---|

| 7075 | 340.85 | 0.6823 | 11.63 |

| 7075-0.2BF | 242.54 | 0.3199 | 6.24 |

| 7075-0.6BF | 287.42 | 0.4327 | 9.04 |

| 7075-1.0BF | 344.96 | 0.8612 | 12.71 |

| 7075-2.0BF | 157.90 | 0.3404 | 4.08 |

The results of friction wear tests show that the addition of basalt fibers has a positive effect on improving the wear resistance of 7075 aluminum alloy, which is consistent with the results reported by other scholars in BF/7075 composites prepared by stir casting and so on [21-23]. However, the properties of extruded state AMCs are anisotropic and the effect of basalt fibers on their wear behavior in different directions has not been studied as a point of interest.

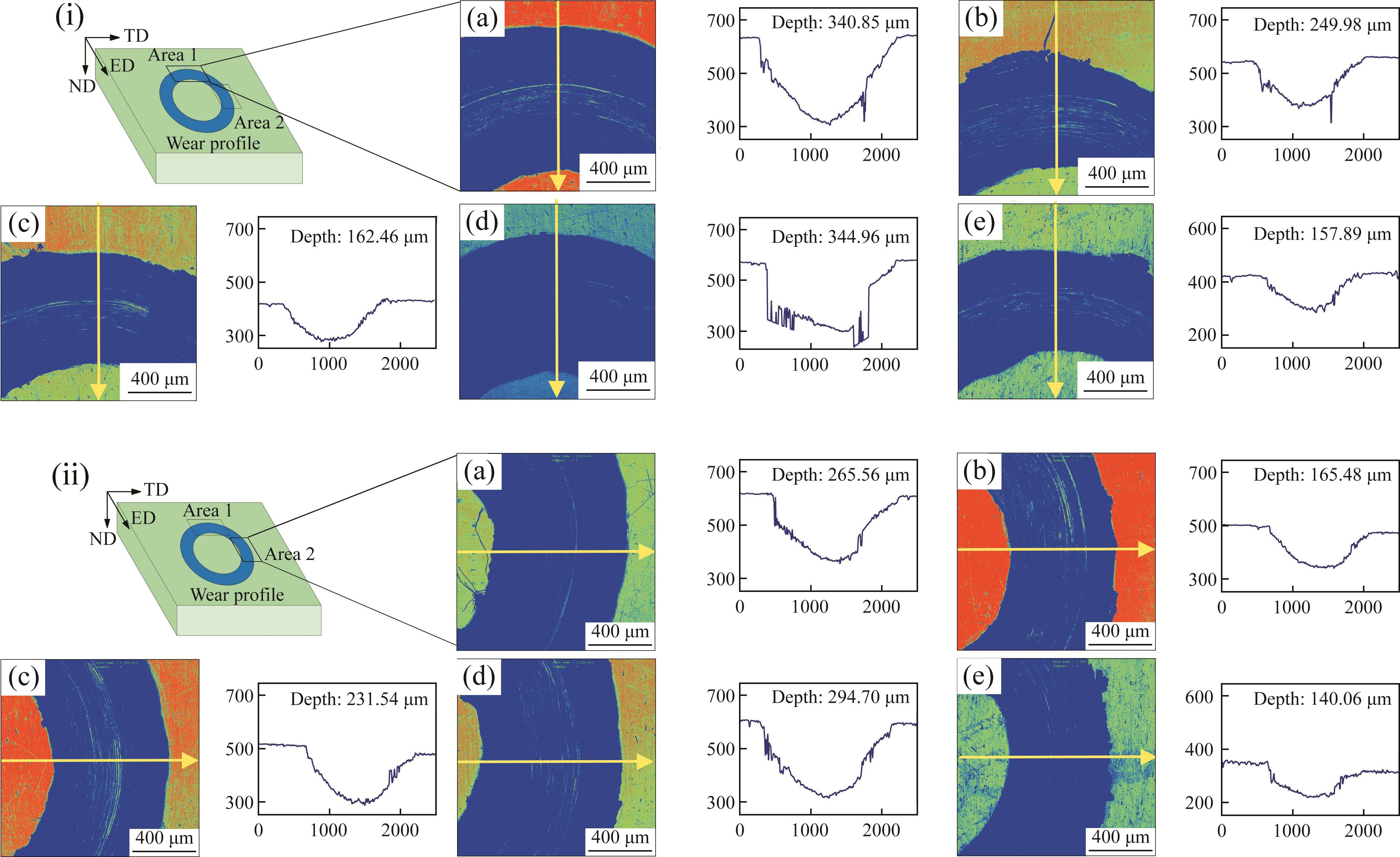

During the wear depth measurement of the samples using laser confocal microscopy, we noticed that the depths of the annular wear grooves differed significantly in different directions. Therefore, we measured and compared the wear depths at different locations of the annular wear grooves on the ED-TD surface of the samples, as shown in Figure 10. The wear depth of Area 1 where the annular wear groove is tangent to the ED is shown in Figure 10(i). The wear depth of Area 2 where the annular wear groove is tangent to the TD is shown in Figure 10(ii).

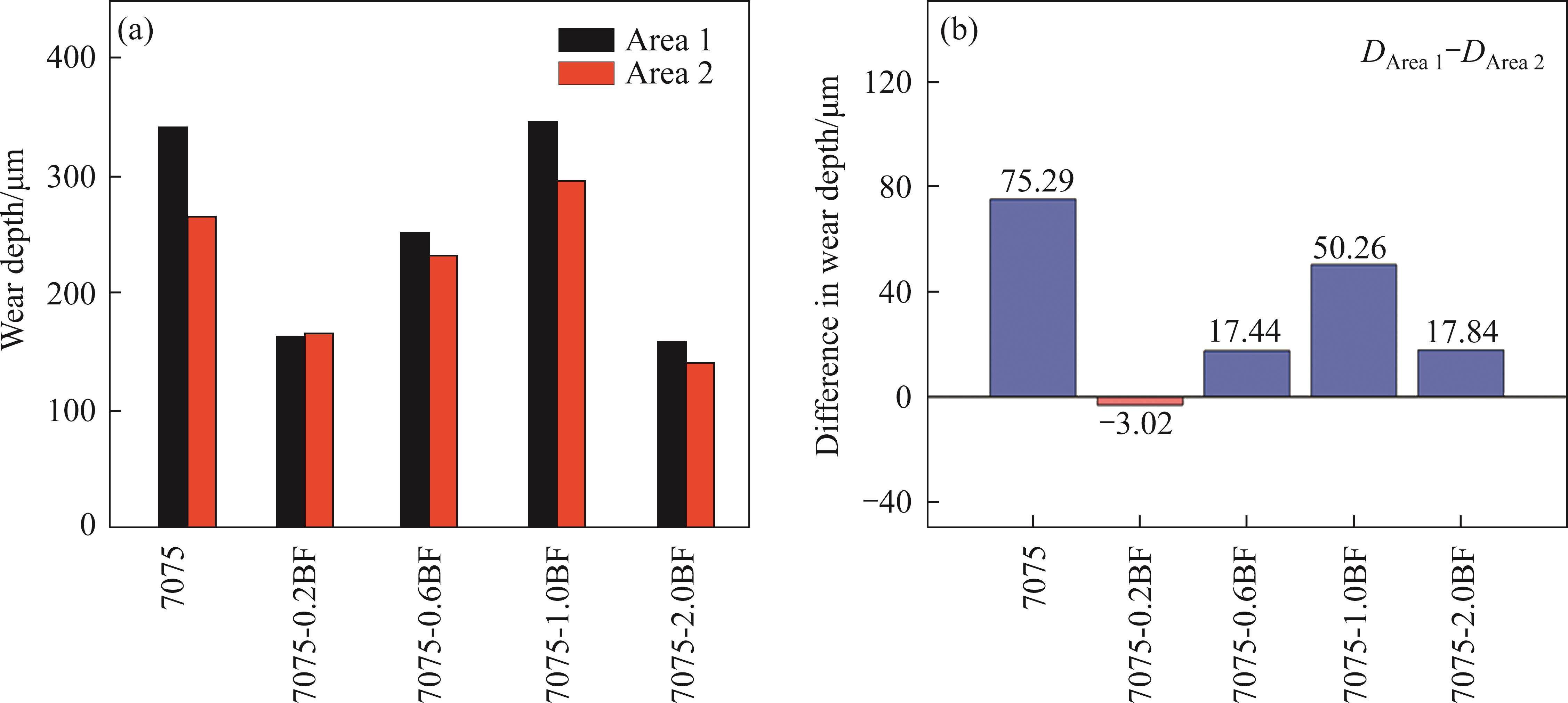

Figure 11(a) demonstrates the trend of wear depth of AMCs with increasing basalt fiber content in Area 1 and Area 2. The depth of wear of the composites in both regions decreases, then increases, and then decreases again with the growth of basalt fiber addition. For the same basalt fiber content, the wear depth of the composites in Area 1 is higher than or close to that in Area 2, which is due to the anisotropy of the extruded alloy properties. At the same time, we notice that the depth difference between Area 1 and Area 2 has a certain pattern of change with the increase of basalt fiber content, as shown in Figure 11(b). The variation of the wear depth difference in different regions is consistent with the variation of wear depth in each region with basalt fiber content. There is reason to believe that the wear inhomogeneity, i.e., the wear depth difference, affects the wear resistance of the alloy.

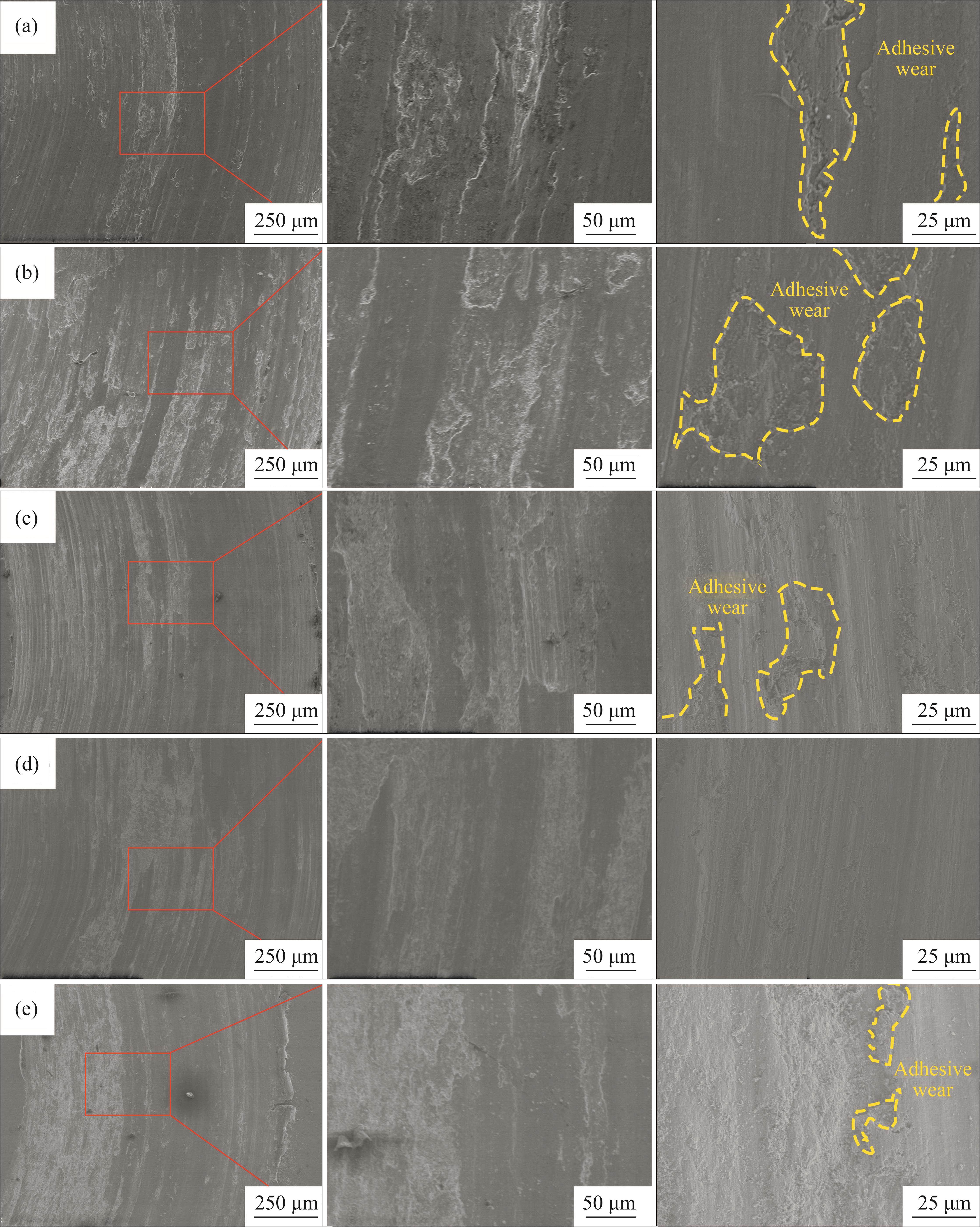

Figure 12 shows the SEM observations of wear grooves on the surface of the samples. As the basalt fiber content increases, there are fewer adhesive wear features in the wear region of the AMCs, and the wear marks become progressively shallower and narrower. Due to the low hardness of the samples, plastic deformation occurred on both sides of the furrows during the wear process, resulting in work hardening, and micro-cracks and abrasive particles were generated in the subsequent friction process. The abrasive particles wore with the surface of the sample by driving force and produced many furrows parallel to the sliding direction. This process included adhesive wear, fatigue spall wear, and abrasive wear. After adding basalt fiber, the depth and number of furrows of the sample were significantly reduced, the friction traces were relatively flat, and the degree of plastic deformation was diminished. Firstly, basalt fibers are more wear-resistant as a hard phase. Moreover, the addition of basalt fibers leads to the emergence of localized fine crystalline areas in the AMCs. The grain boundary area increases and the hardness of the AMCs is improved.

The friction coefficients of the AMCs were slightly changed with basalt fibers addition, but the inhomogeneous wear of the alloys on the ED-TD surface was significantly alleviated. In the 7075 sample, as shown in Figure 10 and Figure 11, the wear depth difference between different areas of the ED-TD surface reaches 75.29 μm, which implies that when the alloy is subjected to circumferential ball friction, the contact area between the steel ball and the alloy is constantly changing under constant load. The alloy matrix is subject to excessive wear in regions where the contact area with the steel ball is large. Excessive wear leads to a greater wear depth, which in turn leads to a greater contact area with the steel ball during subsequent wear, and thus the AMCs exhibit poorer wear resistance. With the addition of basalt fibers, the values of wear depth difference between different areas of the ED-TD surface decreases significantly. The value of wear depth difference of 7075-0.2BF is almost 0. The values of 7075-0.6BF and 7075-2.0BF is only 25% of that of 7075. This indicates that basalt fibers alleviate the uneven wear on the ED-TD surface of the extruded 7075 aluminum alloy, and the circumferential friction of the steel ball is more stable. As a result, the AMC exhibits enhanced wear resistance.

4 Conclusions

1) AMCs prepared by adding basalt fibers to 7075 aluminum alloy have higher hardness and elongation while maintaining tensile strength. Owing to the grain refinement effect and load transfer effect of the fibers, the AMCs have better mechanical properties.

2) Basalt fibers enhanced the wear resistance of the 7075 aluminum alloy. 7075-2.0BF shows the weakest wear, with the smallest values for maximum wear depth and mass loss. The wear volumes of 7075-2.0BF and 7075-0.2BF are close to each other and only about 50% of the wear volume of 7075.

3) The uneven wear of the 7075 aluminum alloy on the ED-TD surface was significantly alleviated with the addition of basalt fibers. The variation of the wear depth difference in different regions is consistent with the variation of wear depth in each region with basalt fiber content. The inhibition of uneven wear by basalt fibers plays a positive role in the enhancement of wear resistance for 7075 aluminum alloy.

Improving corrosion resistanceand corrosive wear resistance of aluminum alloy drill pipe by surface nanocrystallization and micro-arc oxidation

[J]. Journal of Materials Engineering and Performance, 2018, 27(9): 4462-4472. DOI: 10.1007/s1166 5-018-3529-x.Aluminum alloy pipe design and mechanical property analysis

[M]//Lecture Notes in Mechanical Engineering.Effect of La on mechanical properties and precipitated phase stability of 2195 alloy at elevated temperature

[J]. Journal of Materials Engineering and Performance, 2024, 33(19): 10464-10474. DOI: 10.1007/s11665-023-08660-4.Mechanical properties and corrosion resistance enhancement of 2024 aluminum alloy for drill pipe after heat treatment and Sr modification

[J]. Materials Today Communications, 2023, 36: 106805. DOI: 10.1016/j.mtcomm.2023.106805.Sliding wear behaviour of nickel-coated short fibre-reinforced Al7075 composites

[J]. Journal of Failure Analysis and Prevention, 2020, 20(5): 1609-1614. DOI: 10.1007/s11668-020-00955-1.Wear resistance study of bionic pitted Ni cladding layer on 7075 aluminum alloy drill pipe surface

[J]. Coatings, 2023, 13(10): 1768. DOI: 10.3390/coatings13101768.Study the effect of SiC content on the wear behavior and mechanism of as-extruded SiCp/Al-Cu-Mg-Zn alloy under simulating drilling operation

[J]. Surface and Interface Analysis, 2016, 48(8): 853-860. DOI: 10.1002/sia.5891.Effect of extrusion texture on corrosion behaviour of D16T drill pipe in 3.5% NaCl solution

[J]. International Journal of Electrochemical Science, 2018, 13(9): 8970-8982. DOI: 10.20964/2018.09.65.A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites

[J]. Journal of Manufacturing Processes, 2020, 56: 1059-1074. DOI: 10. 1016/j.jmapro.2020.05.042.Fatigue and failure analysis of aluminium and composite automotive wheel rims: Experimental and numerical investigation

[J]. Engineering Failure Analysis, 2023, 146: 107064. DOI: 10.1016/j.engfailanal.2023.107064.Thermophysical properties of Cu-coated carbon fibers reinforced aluminum matrix composites by stir casting

[J]. Carbon Letters, 2023, 33(7): 2053-2061. DOI: 10.1007/s42823-023-00555-7.Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties

[J]. Journal of Manufacturing Processes, 2020, 59: 131-152. DOI: 10.1016/j.jmapro.2020.09.010.Enhancement of mechanical properties of aluminium/epoxy composites with silane functionalization of aluminium powder

[J]. Composites Part B: Engineering, 2012, 43(4): 1743-1748. DOI: 10.1016/j.compositesb.2011.12.010.Effect of annealing process on the interfacial microstructure evolution and mechanical properties of 7050 aluminum alloy clad plates

[J]. Materials Letters, 2022, 324: 132608. DOI: 10.1016/j.matlet.2022.132608.Static and fatigue characterisation of new basalt fibre reinforced composites

[J]. Composite Structures, 2012, 94(3): 1165-1174. DOI: 10.1016/j.compstruct.2011.10.007.Creep behavior of basalt fiber-metal laminate composites

[J]. Composites Part B: Engineering, 2016, 91: 275-282. DOI: 10.1016/j.compositesb.2016.01.017.A review on basalt fibre and its composites

[J]. Composites Part B: Engineering, 2015, 74: 74-94. DOI: 10.1016/j.compositesb. 2014.12.034.Investigation on mechanical properties and failure mechanisms of basalt fiber reinforced aluminum matrix composites under different loading conditions

[J]. Journal of Composite Materials, 2018, 52(14): 1907-1914. DOI: 10. 1177/0021998317733807.Basalt short fibers dispersion and fabric impregnation with magnesium alloy (AZ63): First results

[J]. Materials, 2019, 12(18): 2960. DOI: 10.3390/ma12182960.Basalt fibre reinforced aluminium matrix composites-A review

[J]. Materials Today: Proceedings, 2020, 21: 380-383. DOI: 10.1016/j.matpr.2019.06.135.Dry sliding wear behaviour of basalt short fiber reinforced aluminium metal matrix composites

[J]. Applied Mechanics and Materials, 2014, 592-594: 1285-1290. DOI: 10.4028/www.scientific.net/amm.592-594.1285.Fibre/matrix intermetallic phase formation in novel aluminium-basalt composites

[J]. Materials Letters, 2019, 239: 128-131. DOI: 10.1016/j.matlet.2018.12.079.Experimental investigation of friction and wear properties of a clutch facing made of Al-7075 with basalt fiber metal matrix composite

[J]. Journal of Multiscale Modelling, 2019, 10(2): 1850006-28. DOI: 10.1142/S1756973718500063.Effect of forging parameters on low cycle fatigue behaviour of Al/basalt short fiber metal matrix composites

[J]. The Scientific World Journal, 2013, 2013: 250513. DOI: 10.1155/2013/250513.Preparation and corrosion resistance of short basalt fiber/7075 aluminum composite

[J]. Materials and Corrosion, 2020, 71(11): 1824-1831. DOI: 10.1002/maco.202011771.Microstructure and mechanical properties of fine-grained aluminum matrix composite reinforced with nitinol shape memory alloy particulates produced by underwater friction stir processing

[J]. Journal of Alloys and Compounds, 2019, 786: 257-271. DOI: 10.1016/j.jallcom.2019.01.364.Optimizing the heat treatment of high-strength 7075-type wrought alloys: A metallographic study

[J]. International Journal of Metalcasting, 2016, 10(3): 264-275. DOI: 10.1007/s40962-016-0038-2.Laminate squeeze casting of carbon fiber reinforced aluminum matrix composites

[J]. Materials & Design, 2015, 67: 154-158. DOI: 10.1016/j.matdes.2014.11.034.Mechanical properties of nanodiamond and multi-walled carbon nanotubes dual-reinforced aluminum matrix composite materials

[J]. Materials Science and Engineering A, 2015, 632: 72-77. DOI: 10.1016/j.msea.2015.02.057.Research on preparation and properties of carbon fiber reinforced zinc-based aluminum rich alloy composite

[J]. Materials, 2022, 15(3): 1087. DOI: 10.3390/ma15031087.The influences of interfacial characteristics and subsurface microstructural evolution on wear behavior of Al/A206-5Pct alumina micro/nano-composites

[J]. Metallurgical and Materials Transactions B, 2015, 46(3): 1115-1124. DOI: 10.1007/s116 63-015-0323-0.Research on preparation and properties of carbon fiber reinforced zinc-based aluminum rich alloy composite

[J]. Materials, 2022, 15(3): 1087. DOI: 10.3390/ma15031087.MA Yin-long, SUN Zhi-gang, XIONG Hong-wei, REN Jie, ZHAO Jing-jing, and GUO Cheng-bin declare that they have no conflict of interest.

MA Yin-long, SUN Zhi-gang, XIONG Hong-wei, REN Jie, ZHAO Jing-jing, GUO Cheng-bin. Mechanical properties and wear behavior of extruded basalt fibers/7075 aluminum matrix composites used for drill pipes [J]. Journal of Central South University, 2025, 32(1): 21-33. DOI: https://doi.org/10.1007/s11771-025-5849-y.

马银龙,孙志刚,熊洪威等.钻杆用玄武岩纤维/7075铝基复合材料的力学性能和磨损行为[J].中南大学学报(英文版),2025,32(1):21-33.