1 Introduction

As the main component of energy resources, coal is currently the largest resource of primary energy consumption in China and occupies an important position in the energy structure [1, 2]. With the continuous mining and utilization of coal, the amount of shallow coal resources in China is continuously decreasing, and approximately 70% of China’s coal resources are distributed at depths over 2000 m. Therefore, the development of coal resources must continue to move deeper inside Earth, and kilometer-level mining will soon become the new normal [3, 4]. As the mining depth increases, the mining intensity also increases and the mining layout becomes complex. Additionally, the stress state of the coal surrounding rock gradually deteriorates, resulting in the sharp increase and enhancement of coal and gas outbursts, rock bursts, and other dynamic coal mine disasters [5-7]. Deep coal and rock are in a stress state of “three highs and one disturbance”. During the mining process, coal seams are subjected to dynamic disturbances such as roof fracture, fault slip, engineering blasting, and natural earthquakes. When the dynamic and static loads of the surrounding rock of the roadway exceed its dynamic strength, mining earthquakes occur underground, and may trigger ground pressure accidents [8, 9].

To obtain the dynamic mechanical characteristics of coal at different depths, LI et al [10] used the improved split Hopkinson pressure bar (SHPB) to simulate the initial stress at the depths of 0, 200, 400, 600 and 800 m by applying the hydrostatic pressures of 0, 5, 10, 15 and 20 MPa to the coal. They conducted dynamic mechanical experiments on coal at different depths and investigated the relationship between the dynamic compressive strength of coal with the depth and loading rate. Their results revealed that, under certain loading rate conditions, the dynamic strength is positively correlated with the depth.

Water has great impact on the mechanical properties of coal [11]. In actual production, the coal seam water injection is also an effective method for preventing rockbursts [12]. The coal seam is softened by the coal seam water injection. Under the effect of water pressure, the primary and secondary pore fracture systems continuously absorb water, and the firmness and strength of the coal body are weakened. Consequently, the high stress of the roadway is transferred away from the roadway, reducing the risk of rockburst in the coal seam roadway. To date, many studies have conducted extensive research on the static and dynamic mechanical properties of water-bearing coal. AI et al [13] systematically soaked coal samples obtained from China’s Tashan coal mine for 3 h, 6 h, 12 h, 24 h, 36 h, 2 d, 4 d, 10 d and 20 d. Then, nuclear magnetic resonance, X-ray diffraction, scanning electron microscopy, and ultrasonic testing were used to comprehensively investigate the changes in the water absorption characteristics, pore structure, mineral composition, surface morphology, and wave velocity of the coal samples with the immersion time. Moreover, through uniaxial compression tests, it was found that the uniaxial compressive strength and elastic modulus of coal decreased as the immersion time increased. After 20 d, the uniaxial compressive strength and elastic modulus decreased by 21.9% and 28.53%, respectively. YAO et al [14] prepared 12 coal samples with the water contents of 0%, 2.37%, 3.78% and 5.29%, respectively, for acoustic emission testing under uniaxial compression. The uniaxial test revealed that, as the water content of the samples increased, the peak stress, elastic modulus, strain-softening modulus, and post-peak modulus decreased, while the peak strain increased. ZHOU et al [15] conducted uniaxial compression tests on dry, partially saturated, quasi-saturated, and fully saturated coal samples. Their test results revealed that, as the water saturation increased, the coal’s mechanical strength generally decreased, and the failure mode of coal samples changed from dynamic to quasi-static, and from compression shear to tensile failure. LYU et al [16] conducted uniaxial compression tests on coal samples under various immersion environments using a water-rock-gas coupling test system. They analyzed the macroscopic and mesoscopic deterioration mechanisms of coal under water-gas coupling conditions and found that, under three different immersion conditions, the compressive strength of the coal samples was lower than that of the dry coal samples. TANG et al [17] investigated the effect of moisture content on the mechanical properties and failure behavior of coal samples, and found that the uniaxial compressive strength, elastic modulus, and strain softening modulus of the coal samples decreased almost linearly with the moisture content. LIU et al [18] conducted laboratory studies on the mechanical properties and failure behavior of dry and water-saturated anisotropic coal samples under different true triaxial loading stresses. Their results revealed that the presence of water significantly reduced the strength, elastic modulus, and strength anisotropy of coal. The findings of the above-mentioned studies indicate that the water content has significant impact on the static mechanical properties of coal. Similarly, some studies have shown that the water content has significant impact on the dynamic mechanical properties of coal. GU et al [19-21] soaked coal samples for different time, and then conducted dynamic mechanical experiments to obtain the dynamic compressive strength and elastic modulus of coal. As the soaking time increased, these properties first increased and then decreased. WEI et al [22] conducted experiments on circular coal samples with different water contents using the SHPB. Their results revealed that, under different loading pressures, the dynamic peak stress exhibited a concave bending trend as the water content increased. WANG et al [23] conducted dynamic mechanical experiments on coal samples with different water contents using the SHPB. Their results revealed that, under one-dimensional static and dynamic loading, the dynamic strength of coal samples saturated for seven days was lower than that of natural coal samples.

The findings of the above-mentioned studies revealed that water has significant impact on the static and dynamic mechanical properties of coal, and there are also significant differences in the dynamic mechanical properties of coal at different depths. However, whether the dynamic mechanical properties of water-bearing coal at different depths will change with the water content and depth has not been investigated to date.

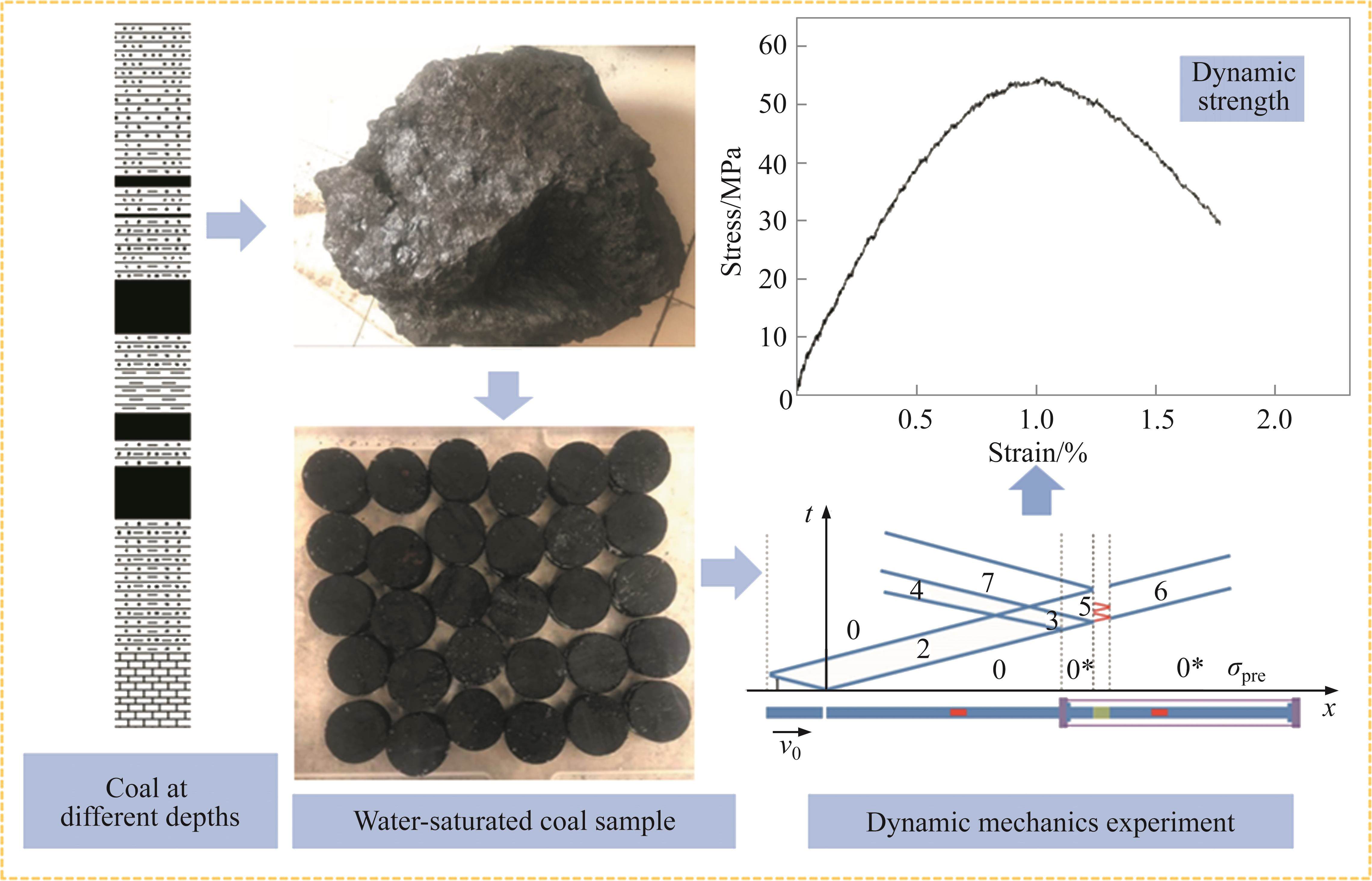

To address this research gap, this study obtained samples from Pingdingshan Coal Mine, immersed the processed coal samples in water to obtain saturated coal samples, and then applied the static water pressures of 0, 5, 10, 15 and 20 MPa to the coal using the improved SHPB to simulate the initial stress at the depths of 0, 200, 400, 600 and 800 m. Dynamic mechanical experiments were conducted on the saturated coal at different depths to obtain the dynamic strength of saturated coal at different depths and compare the dynamic strength of coal at different depths under natural conditions. The findings of this study provide a basic theoretical foundation for the prevention and control of dynamic coal mine disasters.

2 Sample preparation

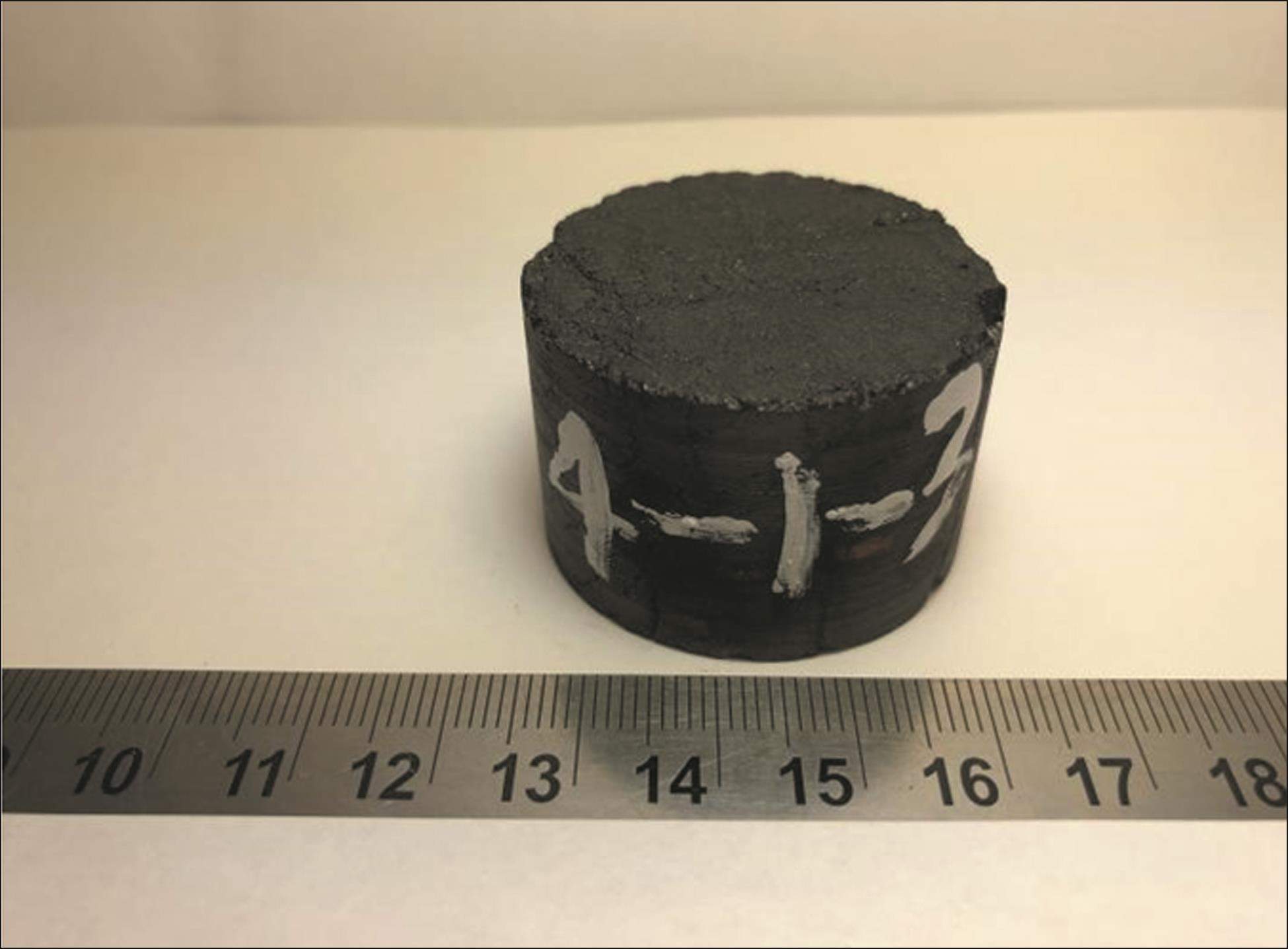

The coal samples used in this experiment were obtained from the Ji-24130 protective layer working face of the tenth coal mine at Pingdingshan Coal Mine in Henan Province, China. The samples were processed using the method recommended by the International Society of Rock Mechanics (ISRM) [24]. The sample diameter was 38 mm and the height was 25 mm, as shown in Figure 1. To eliminate the influence of bedding on the properties of coal, all drilling was conducted with the drilling direction uniformly parallel to the bedding direction during sample preparation.

To obtain coal samples in a water-saturated state, the processed coal samples were immersed in water, as shown in Figure 2.

3 Experimental setups

3.1 Experimental equipment

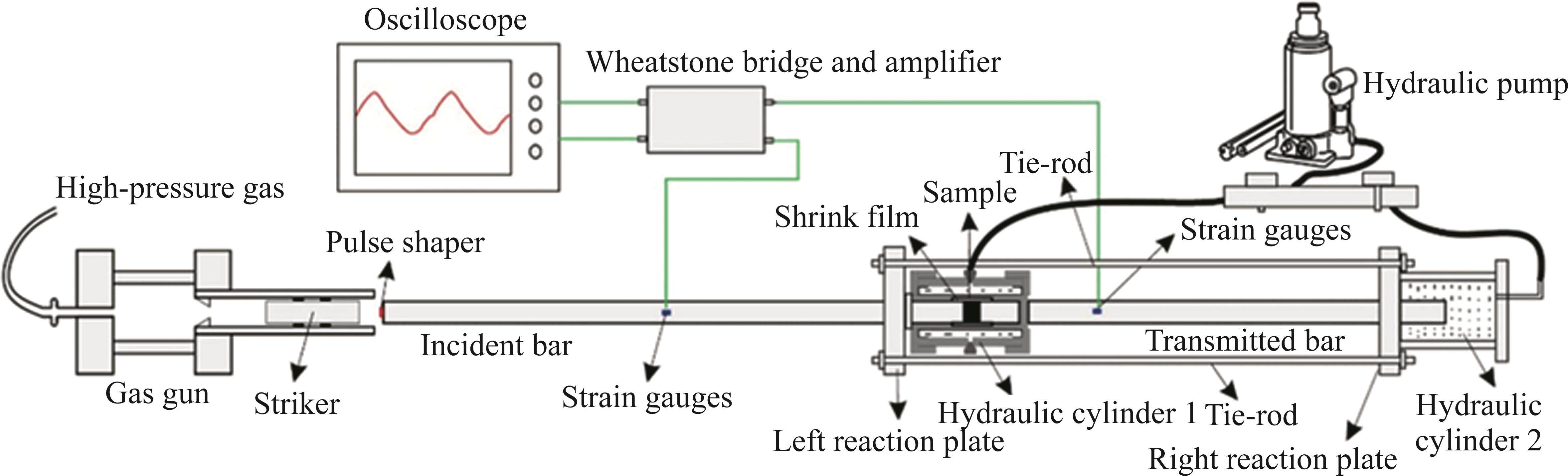

This study used the experimental SHPB device improved by the University of Toronto in Canada [25-27], as shown in Figure 3. Specifically, an axial compression device and a confining pressure device have been added to the traditional SHPB device. Axial prestress is applied through the axial compression device, and confining pressure is applied through the confining pressure device.

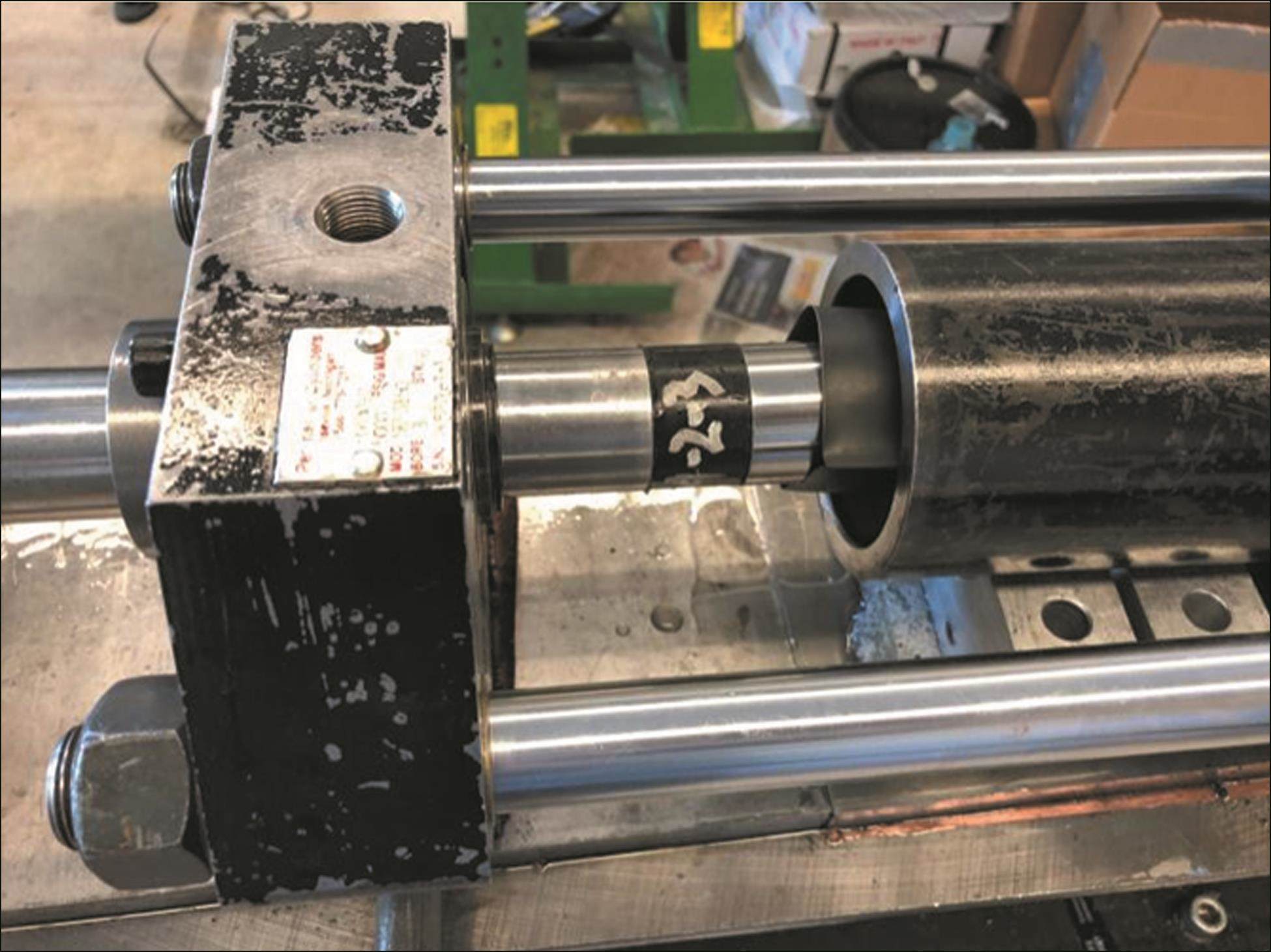

The average density of the overlying strata is approximately 2500 kg/m3. Using the formula P=ρgh, we can determine the initial hydrostatic pressure at various depths. To further investigate the influence of water content on the dynamic mechanical properties of coal under different depth conditions, the improved SHPB was used to simulate the initial stress state of the saturated coal samples under the initial hydrostatic pressures of 5, 10, 15 and 20 MPa at the depths of 200, 400, 600 and 800 m. Subsequently, dynamic mechanical experiments were conducted. The saturated coal samples used in the experiment are shown in Figure 4.

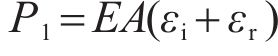

In the test, the coal sample was clamped between the incident rod and the transmission rod. Driven by high-pressure nitrogen, the bullet hit the incident rod to produce an incident wave. When the incident wave reached the contact surface between the incident rod and the sample, part of the wave was reflected and propagated backward, while the other part formed a transmission wave, which propagated along the transmission rod. By collecting the incident wave strain signals, reflected wave strain signals, and transmitted wave strain signals through strain gauges, the forces P1 and P2 at both ends of the sample were calculated [28] as follows:

where E is elastic modulus of the rod, and A is the rod area.

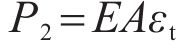

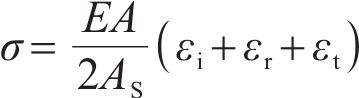

where AS is the initial area of the sample.

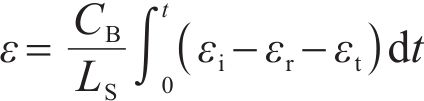

The average strain in the sample is expressed as follows [29]:

where CB is the elastic wave velocity in the rod, and LS is the initial length of the specimen.

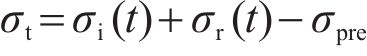

3.2 Dynamic stress balance

To ensure the effectiveness of the dynamic testing of coal, the verification of dynamic stress balance was carried out. Compared with coal under uniaxial compression, coal under hydrostatic pressure has a certain amount of axial prestress before dynamic loading is applied, which must be considered during the dynamic stress balance. Based on one-dimensional stress wave theory, it can be concluded that the following relationship holds [25]:

where

According to the method recommended by ISRM [24], a circular copper plate with a diameter of 10 mm and thickness of 0.8 mm was used to transform the incident wave from a rectangle to a sinusoidal curve. The dynamic stress balance diagram of the coal and rock at the depth of 600 m is shown in Figure 5. As can be seen, in typical dynamic experiments, the forces at both ends of the sample were approximately equal at the peak, indicating that dynamic equilibrium was achieved at both ends of the coal sample. When the dynamic stress is balanced, the dynamic compressive stress can be calculated using Eq. (3). In this study, the method adopted by LI et al [10] was used to calculate the loading rate.

4 Results and discussion

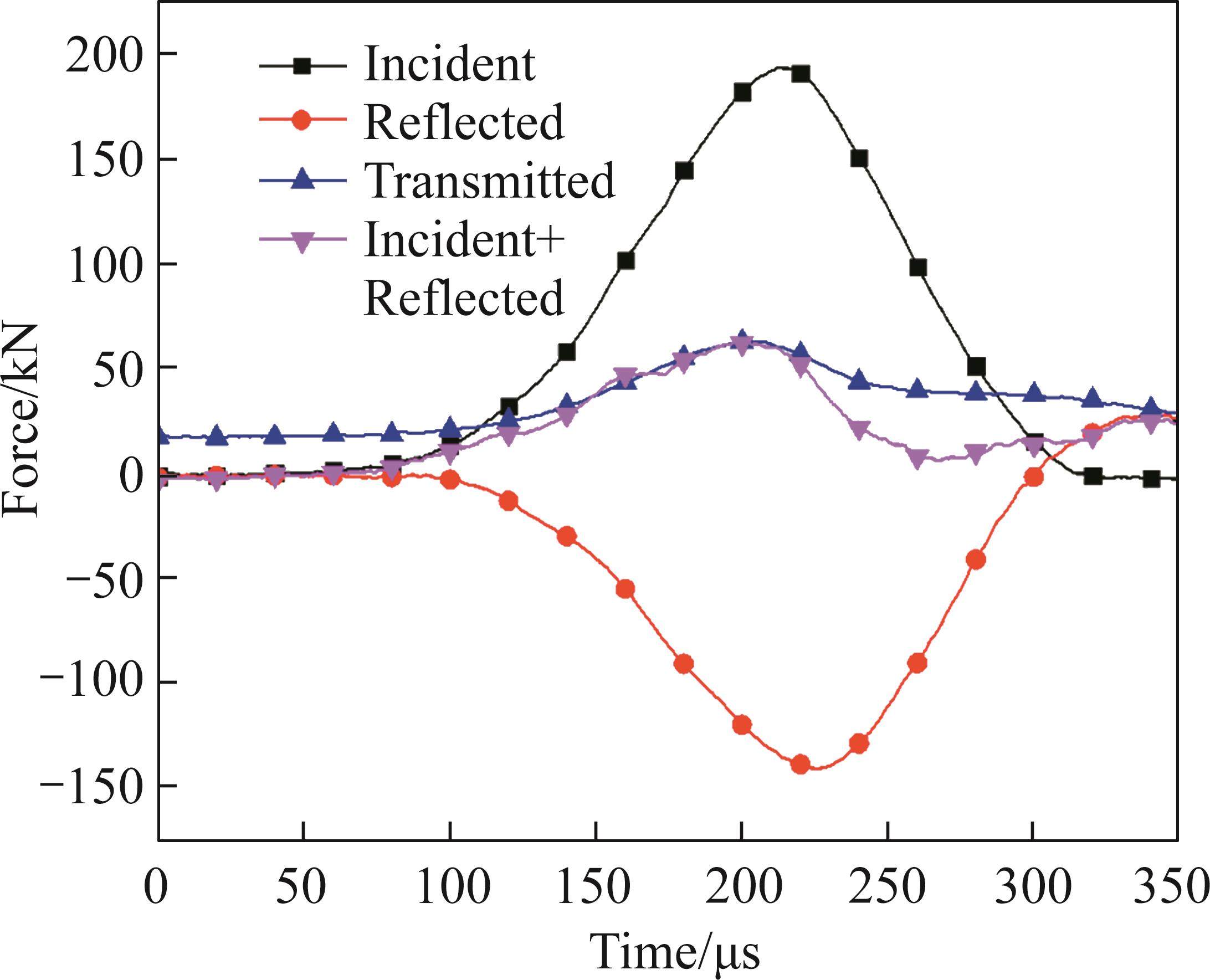

4.1 Influence of water content on dynamic compressive strength of coal

The improved SHPB was used to conduct dynamic tests on coal in both its natural and water-saturated states, without applying initial confining pressure and axial pressure. The dynamic compressive strength of coal in the natural and water-saturated states under different loading rates was measured. The results obtained by the dynamic mechanical test on coal under uniaxial and non-lateral compression are shown in Figure 6. As can be seen, under the same loading rate, the dynamic compressive strength of the coal samples in the water-saturated state decreased to varying degrees, indicating that water saturation weakened the strength of coal samples. Both in the natural and saturated conditions, the dynamic strength of coal increased with the loading rate.

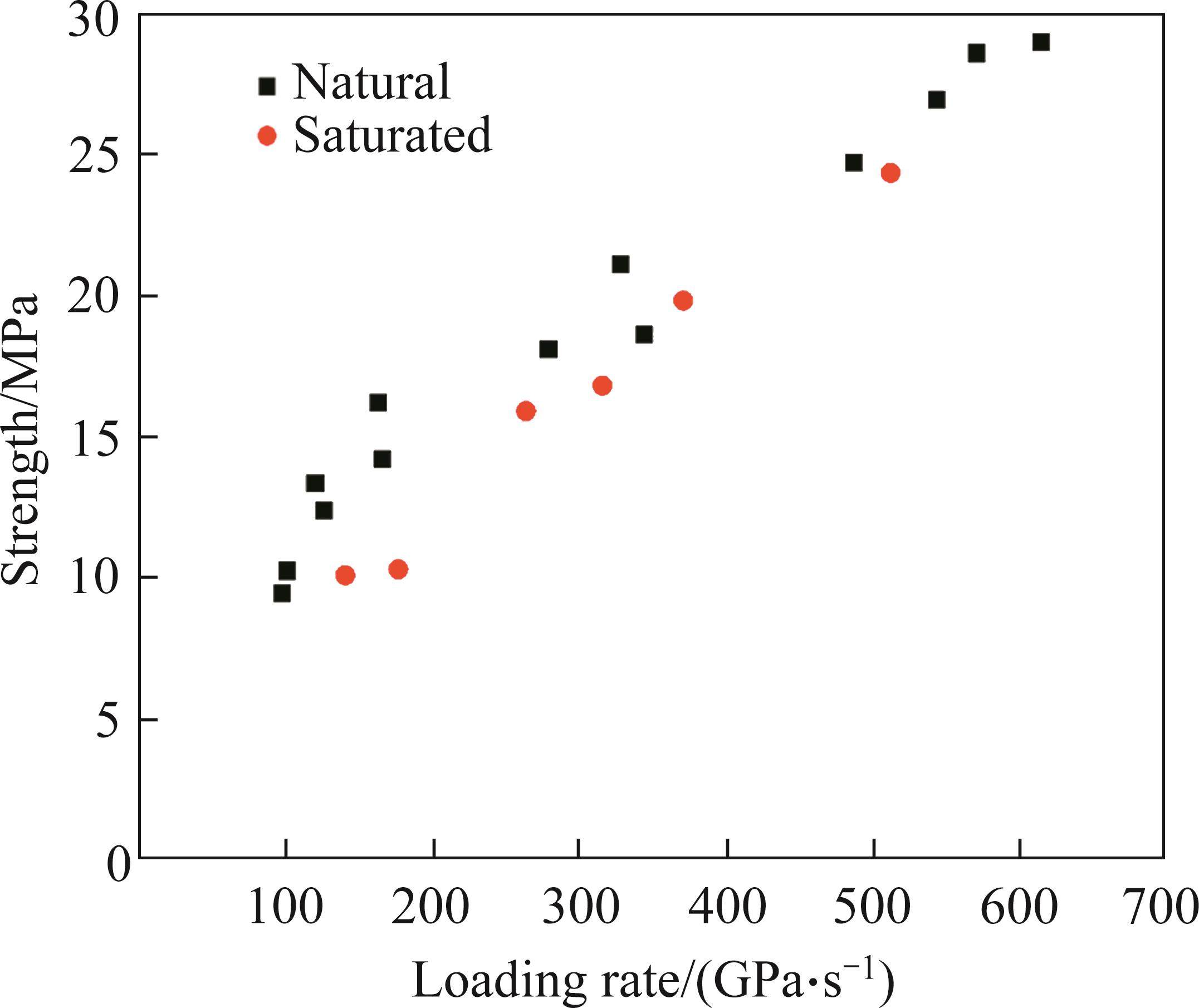

4.2 Dynamic strength of saturated coal at different depths

Using the improved SHPB, the initial hydrostatic pressures of 5, 10, 15, and 20 MPa were applied to the saturated coal samples to simulate the initial stress state at the depths of 200, 400, 600 and 800 m. Then, dynamic compression tests were conducted to obtain the dynamic compressive strength of saturated coal at different depths, as shown in Figure 7. As can be seen, the dynamic strength of saturated coal varied with the depth and loading rate, similar to the natural state, exhibiting significant rate correlation. The dynamic strength gradually increased with the loading rate, and the rate of increase diminished as the loading rate reached a certain threshold. Moreover, the dynamic strength of coal varied significantly with the depth, particularly when the depth increased from 0 to 200 m. As the depth gradually increased, the growth rate slowed down.

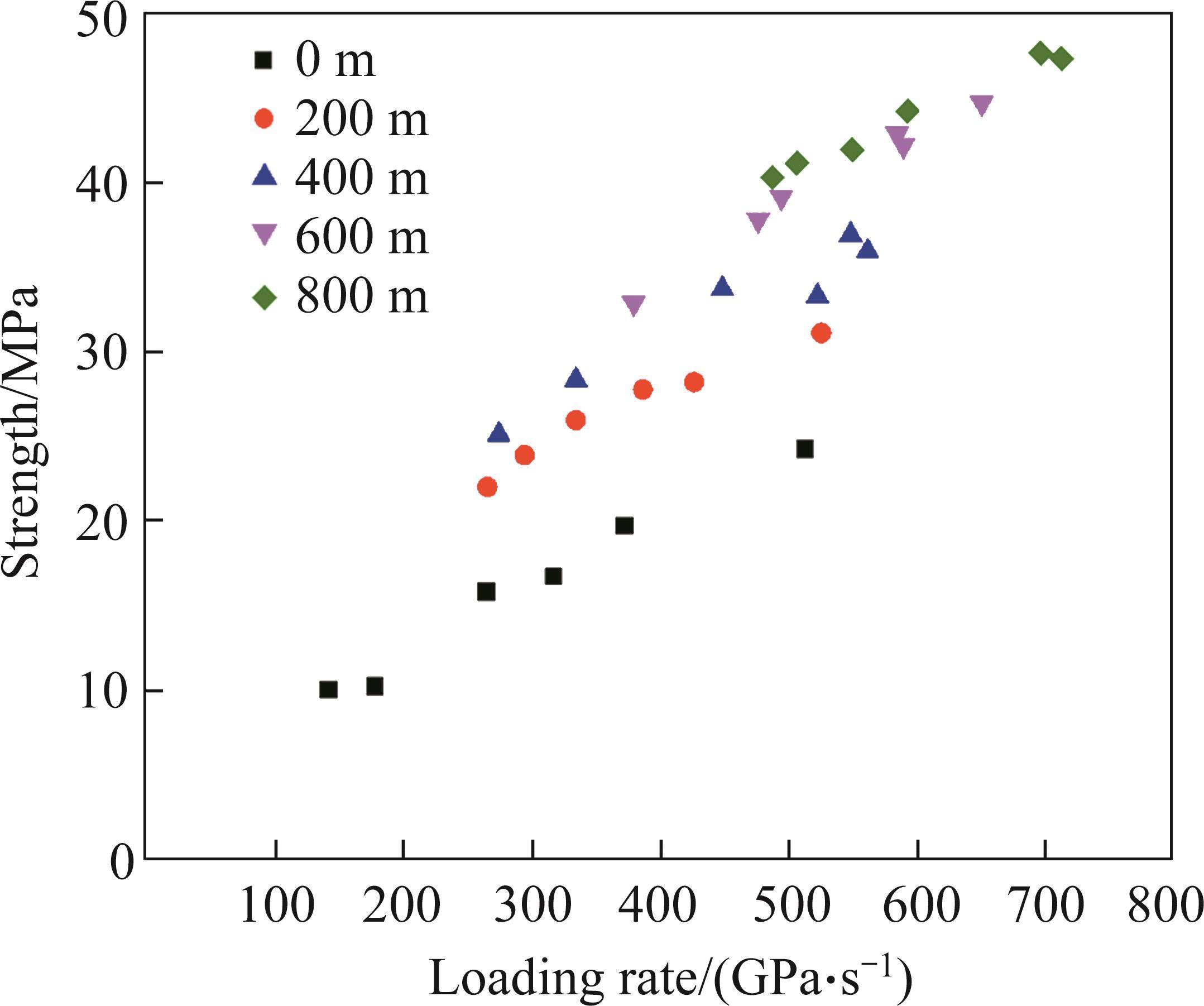

4.3 Dynamic strength of coal under different depth stress states in natural and saturated states

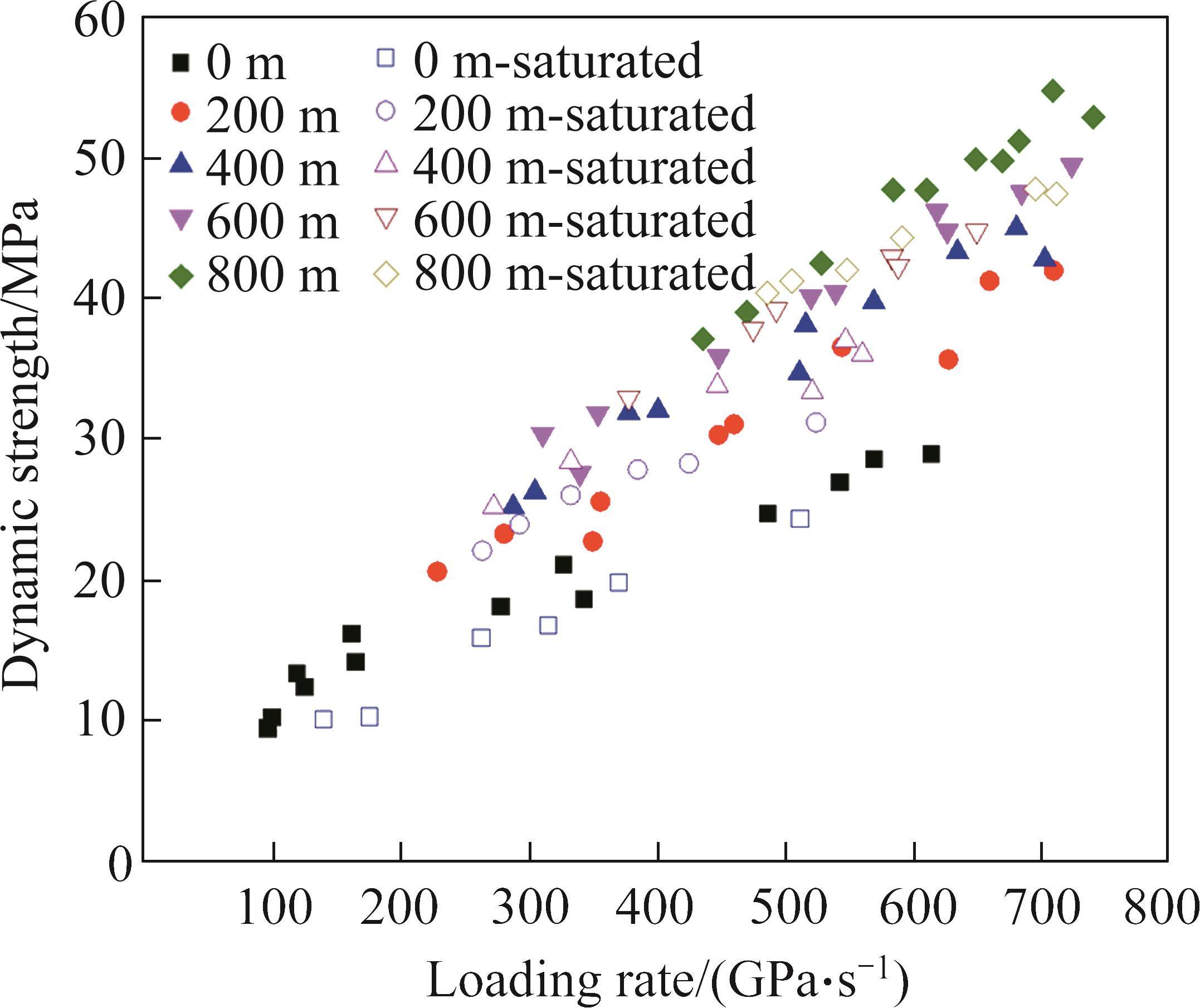

LI et al [10] investigated the dynamic strength of coal under natural conditions at different depths. In this study, the dynamic strength of coal under natural conditions at different depths was compared with the dynamic strength of coal under saturated conditions at different depths, as shown in Figure 8. As can be seen, the dynamic strength of coal under different depth conditions weakened compared with that in the natural state, indicating that the saturated condition decreased the dynamic strength of coal and rock at different depths. However, for 0 m, the reduction in the dynamic compressive strength of coal and rock in the saturated state at 200, 400, 600 and 800 m was significantly reduced compared with that in the natural state.

The strength of coal is influenced by various factors. On the one hand, water saturation weakens the overall properties of coal and rock; on the other hand, the presence of free water surface tension and the Stefan effect produce resistance that hinders crack propagation, resulting in the increase of dynamic strength. Additionally, the deep confining pressure exacerbates the increase in resistance.

5 Conclusions

This study conducted dynamic mechanical tests on saturated coal samples at different depths using the improved SHPB. The initial hydrostatic pressures of 5, 10, 15 and 20 MPa were applied to simulate the initial stress state at the depths of 200, 400, 600 and 800 m. The following conclusions were drawn:

1) Under uniaxial compression without lateral compression, the dynamic compressive strength of the coal sample decreased to varying degrees in the water-saturated state, and the water saturation weakened the strength of the coal sample.

2) Under different depth stress conditions, the dynamic strength of saturated coal varied with the depth and loading rate, similar to the natural state, exhibiting significant rate correlation. Then, the dynamic strength gradually increased with the loading rate, and the rate of increase decreased when the loading rate increased to a certain extent.

3) Compared with that at 0 m, the reduction in the dynamic compressive strength of the coal and rock in the saturated state at 200, 400, 600 and

800 m was significantly reduced compared with that in the natural state.

Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper

[J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1475-1490. DOI: 10.1007/s00603-018-1509-y.Mechanical behavior of coal under different mining rates: A case study from laboratory experiments to field testing

[J]. International Journal of Mining Science and Technology, 2021, 31(5): 825-841. DOI: 10.1016/j.ijmst.2021.06.007.Calculating changes in fractal dimension of surface cracks to quantify how the dynamic loading rate affects rock failure in deep mining

[J]. Journal of Central South University, 2020, 27(10): 3013-3024. DOI: 10.1007/s11771-020-4525-5.Mechanical behavior of coal under true triaxial loading test connecting the effect of excavation- and mining-induced disturbances

[J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2023, 9(1): 34. DOI: 10.1007/s40948-023-00570-y.In situ observation and evaluation of zonal disintegration affected by existing fractures in deep hard rock tunneling

[J]. Engineering Geology, 2018, 242: 1-11. DOI: 10.1016/j.enggeo.2018.05.019.Deformation-based support design for highly stressed ground with a focus on rockburst damage mitigation

[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2022, 14(1): 50-66. DOI: 10.1016/j.jrmge. 2021.05.007.Excavation-induced damage studies at the Underground Research Laboratory

[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1413-1426. DOI: 10.1016/j.ijrmms. 2004.09.010.State of the art review on mechanism and prevention of coal bumps in China

[J]. Journal of China Coal Society, 2014, 39(2): 205-213. DOI: 10.13225/j.cnki.jccs.2013.0024.Fault-induced coal burst mechanism under mining-induced static and dynamic stresses

[J]. Engineering, 2021, 7(5): 687-700. DOI: 10.1016/j.eng.2020.03.017.Dynamic compressive failure of coal at different burial depths

[J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2023, 9(1): 53. DOI: 10.1007/s40948-023-00589-1.Effects of water on mechanical behavior and acoustic emission characteristics of coal in Brazilian tests

[J]. Theoretical and Applied Fracture Mechanics, 2022, 122: 103636. DOI: 10.1016/j.tafmec.2022.103636.Mechanism of rock burst occurrence in specially thick coal seam with rock parting

[J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1953-1965. DOI: 10.1007/s00603-015-0894-8.Changes in the structure and mechanical properties of a typical coal induced by water immersion

[J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104597. DOI: 10.1016/j.ijrmms.2020.104597.Effects of water intrusion on mechanical properties of and crack propagation in coal

[J]. Rock Mechanics and Rock Engineering, 2016, 49(12): 4699-4709. DOI: 10.1007/s006 03-016-1079-9.Experimental study on the mechanical behavior of coal samples during water saturation

[J]. ACS Omega, 2021, 6(49): 33822-33836. DOI: 10.1021/acsomega.1c05077.Deterioration of compressive properties of coal rocks under water and gas coupling

[J]. Journal of Central South University, 2024, 31(2): 477-495. DOI: 10.1007/s11771-024-5583-x.Effects of water content on mechanical failure behaviors of coal samples

[J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2022, 8(3): 87. DOI: 10.1007/s40948-022-00382-6.Mechanical properties and failure behavior of dry and water-saturated anisotropic coal under true-triaxial loading conditions

[J]. Rock Mechanics and Rock Engineering, 2020, 53(11): 4799-4818. DOI: 10.1007/s00603-019-02035-9.Dynamic response and failure mechanism of fractured coal under different soaking times

[J]. Theoretical and Applied Fracture Mechanics, 2018, 98: 112-122. DOI: 10.1016/j.tafmec. 2018.09.001.Dynamic fracture behaviour and evolution mechanism of soft coal with different porosities and water contents

[J]. Theoretical and Applied Fracture Mechanics, 2019, 103: 102265. DOI: 10.1016/j.tafmec.2019.102265.The effects of water content and external incident energy on coal dynamic behaviour

[J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 123: 104088. DOI: 10.1016/j.ijrmms.2019.104088.Dynamic tensile properties, deformation, and failure testing of impact-loaded coal samples with various water content

[J]. Scientific Reports, 2021, 11(1): 7096. DOI: 10.1038/s41598-021-866 10-7.Strength and failure characteristics of natural and water-saturated coal specimens under static and dynamic loads

[J]. Shock and Vibration, 2018, 2018(1): 3526121. DOI: 10.1155/2018/3526121.Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials

[J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 49: 105-112. DOI: 10.1016/j.ijrmms.2011.10.004.Dynamic tensile failure of rocks under static pre-tension

[J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 80: 12-18. DOI: 10.1016/j.ijrmms.2015. 09.003.An experimental study of dynamic tensile failure of rocks subjected to hydrostatic confinement

[J]. Rock Mechanics and Rock Engineering, 2016, 49(10): 3855-3864. DOI: 10.1007/s006 03-016-0946-8.Experimental study of the dynamic shear response of rocks using a modified punch shear method

[J]. Rock Mechanics and Rock Engineering, 2019, 52(8): 2523-2534. DOI: 10.1007/s00603-019-1744-x.An investigation of the mechanical properties of materials at very high rates of loading

[J]. Proceedings of the Physical Society Section B, 1949, 62(11): 676-700. DOI: 10.1088/0370-1301/62/11/302.Classic split-Hopkinson pressure bar testing

[M]//Mechanical Testing and Evaluation.LI Sheng-wei, GAO Ming-zhong, LI Ye-xue, WANG Jun and ZENG Gang declare that they have no conflict of interest.

LI Sheng-wei, GAO Ming-zhong, LI Ye-xue, WANG Jun, ZENG Gang. Effect of water on dynamic mechanical properties of coal under different depth stress conditions [J]. Journal of Central South University, 2025, 32(1): 220-228. DOI: https://doi.org/10.1007/s11771-025-5864-z.

李圣伟,高明忠,李业学等.水对不同深度应力条件下煤岩动态力学特性的影响[J].中南大学学报(英文版),2025,32(1):220-228.