1 Introduction

As a traditional high-carbon high-chromium steel, Cr12MoV steel is widely used in industrial fields such as cold-extruded feelers, wear-resistant parts, punching dies, cold heading dies [1, 2]. In order to bear harsh working conditions, surface modification is need to conduct on Cr12MoV steel to obtain excellent surface properties such as high hardness, high wear resistance and micro-deformation [3]. Presently, the traditional methods, carburizing, nitriding, and other heat treatment, are widely applied to treat steels surface, which are expensive, inefficient, and high requirements for thermal processing technology and heat treatment process, and even premature failure of the mold occurs when improper processing technology is conducted [4, 5]. Laser cladding, as an emerging surface modification technology, can obtain unique surface properties, such as wear property, by cladding a thin coating on substrate [6-8]. The coating on substrate fabricated by laser cladding has some advantages, such as low heat input and dilution rate, high design freedom and excellent metallurgical bonding between the cladding layer and the substrate, as well as reduced production cost and improved production efficiency [9-11].

High-entropy alloys (HEAs), an emerging alloy composed of five or more elements as principal components, are proposed firstly by YEH et al [12]. Due to the advantages of high entropy alloys such as high hardness, high strength, excellent wear resistance and thermal stability, HEAs have attracted great attention and have been extensively applied in many fields [13-15]. Numerous studies indicated that HEAs containing Mo usually possess excellent hardness, wear resistance and oxidation resistance [16-18], compared to conventional HEAs such as FeCoCrNi. Due to the large atomic size (1.363 Å) in Mo atoms, solid solution and precipitation strengthening easily occur in Mo-contained HEAs, which can improves the properties of the coatings [19]. Among them, the CoCrFeNiMo system, owing to the generation tendency of high hard intermetallic compounds reacted between Mo with Co, Cr and Fe, is presented as a eutectic high-entropy alloy with excellent physical and mechanical properties [20, 21]. WU et al [22] prepared FeNiCoCrMox (x: atomic ratio, x=0, 0.15, 0.20, 0.25) HEA coatings on 316 stainless steel surface using laser cladding, a maximum increase in the hardness of up to 90.5% and a significant reduction in the average friction coefficient were obtained from the HEA coatings compared to the substrate. FU et al [23] prepared CoCr2FeNiMox (x is the atomic ratio, x=0, 0.1, 0.2, 0.3, 0.4) HEA coatings by laser cladding and the results showed that Mo content improved the hardness and wear resistance of the coatings significantly. In order to further improve the wear resistance of the substrate, WC [24], Al2O3 [25], SiC [26] and B4C [27], as reinforcements with high hardness, were added to prepare metal-based composite coatings with excellent abrasion resistance and wear resistance. Among them, WC particles have been widely used due to their high hardness, good abrasion resistance, high melting point, good stability, and well wetting property [28]. PENG et al [29] prepared 20%WC/CoCrFeNi HEA composite coatings with good wear resistance using laser cladding technology. The friction coefficient was low and stable, and the volumetric wear rate was reduced to 0.7×10-5 mm3/(N·m). JIANG et al [30] prepared WCx/(Al1.8CrCuFeNi2 HEA)1-x (x=0, 10 wt.%, 20 wt.%, 30 wt.%, 50 wt.% or 70 wt.%) composite coatings on Ti-6Al-4V substrates by laser cladding technology. The results showed that the coating has the highest hardness (HV0.2 1372.6) at x=30%, and the lowest average coefficient of friction (0.49) as well as the reduced wear rate (6.52×10-7 mm3/(N·m)) was maintained.

CoCrFeNiMo HEAs are potential excellent wear-resistant coating materials to meet the aggressive demand in engineering field, and WC particles are an effective strengthening phase to further improve the hardness and wear resistance of the coating. In this work, WC particles reinforced CoCrFeNiMo composite coatings with different WC particles content were prepared on Cr12MoV steel surface using laser cladding to improve the hardness and wear resistance of substrate. The microstructure evolution, hardness and wear resistance of the composite coatings were studied in detail.

2 Experimental procedures

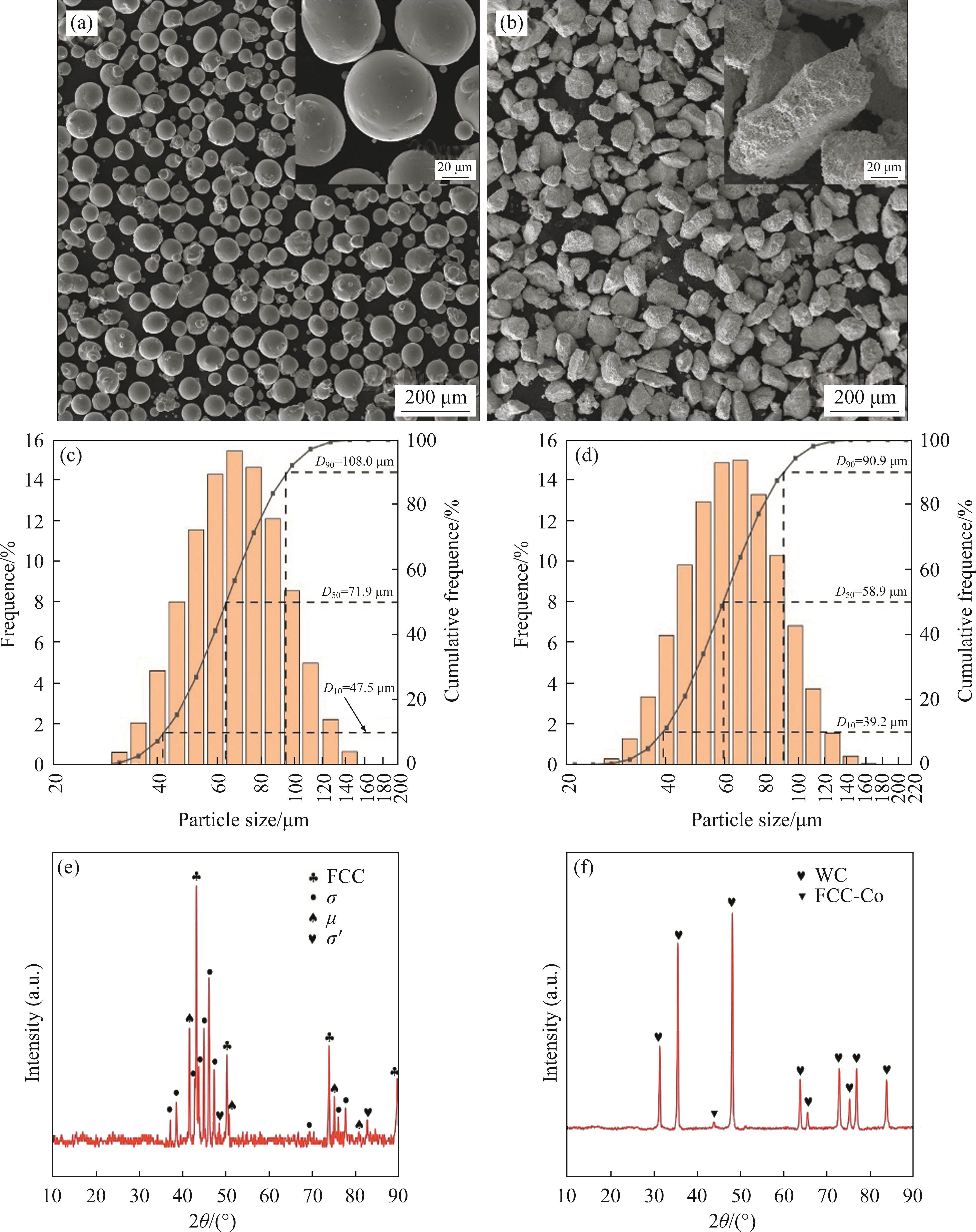

In this work, Cr12MoV steel plate with sizes of 200 mm (length) × 200 mm (width) × 15 mm (thickness) was machined as substrate for laser cladding, and the steel composition is shown in Table 1. The surface of the substrate was sandblasted and cleaned with alcohol to remove oil and contaminants before the experiment. Spherical CoCrFeNiMo high-entropy alloy powders with a particle size distribution of 35-144 μm was selected as the coating matrix material, and powders compositions are shown in Table 2. The WC particles with a particle size distribution of 30-144 μm was used as reinforcement phase. Figure 1 displays the morphology, particle size distribution, and XRD patterns for the two initial powders. The XRD analysis indicates that the powders primarily comprise the FCC phase (JCPDS card No. 47-1417) with specific dimensions (a=3.61756 Å, d=2.0886 Å (111)). Moreover, alongside the FCC phase, the diffraction peaks for σ and μ phases were identified. Both σ and μ phases exhibit a tetragonal structure (JCPDS card No. 09-0050) with dimensions (a=9.171 Å, c=4.741 Å, c/a=0.5183) and a rhombohedral structure (JCPDS card No. 29-0489) with respective dimensions (a=3.687 Å, c=25.617 Å, c/a=6.9479). These phases are identical to the results in Refs. [21, 31]. Additionally, the powder exhibited faint peaks of the σ′ phase, characterized by a tetragonal structure (JCPDS card No. 09-0052), which is also found in Ref. [32]. The result of Figure 1(f) shows that the diffraction peaks are in good agreement with the WC standard diffraction peaks (JCPDS card No. 73-0471). Meanwhile, a weak FCC peak was detected, which is from a small amount of α-Co in the particles as a WC binder. The CoCrFeNiMo HEA powders and WC powders were mixed using planetary ball mill (Nan Da Instrument QM-3SP4) with a ball-to-powder ratio (BPR) of 12:1 under a high purity argon (99.99%) atmosphere for 2 h as the cladding material. Afterwards, it was dried in a drying oven at 120 ℃ for 2 h. It is indicated that the CoCrFeNiMo HEA powders with different WC contents (0, 10 wt.%, 20 wt.% or 30 wt.%) were marked as shown in Table 3 for the sake of simplicity.

| C | Mn | Cr | Si | Mo | V | Fe |

|---|---|---|---|---|---|---|

| 1.48 | 0.26 | 11.60 | 0.24 | 0.48 | 0.21 | Bal. |

| Element | x/% | w/% |

|---|---|---|

| Fe | 19.09 | 16.51 |

| Co | 19.67 | 17.92 |

| Cr | 21.51 | 17.27 |

| Ni | 18.53 | 16.88 |

| Mo | 21.20 | 31.42 |

| Marked symbol | Composition |

|---|---|

| A | CoCrFeNiMo HEA+0 wt.% WC |

| B | CoCrFeNiMo HEA+10 wt.% WC |

| C | CoCrFeNiMo HEA+20 wt.% WC |

| D | CoCrFeNiMo HEA+30 wt.% WC |

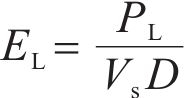

A laser cladding integrated system, as shown in Figure 2, was used in the experiment, which was composed of a computer numerical control (CNC), a laser system, a laser chiller, a coaxial powder feeding system and a 6000 W fiber laser (YLS-400-CTC-Y11) with the wavelength of 1030 nm. Meanwhile, the experiments were performed in a controlled environment with an oxygen concentration of less than 30×10-6 to protect the molten pool from oxidation. The experimental parameters of laser cladding used in this work are shown in Table 4. Here, the linear energy density (EL) is utilized to assess the thermal input in laser cladding, and its calculation is given by [33]:

| Parameter | Value |

|---|---|

| Laser power/W | 1600 |

| Spot diameter/(mm×mm) | 14×2 |

| Scanning speed/(mm∙min-1) | 150 |

| Powder feeding rate/(g∙min-1) | 12 |

| Cladding distance/mm | 100 |

| Shielding gas | Argon (99.99%) |

| Gas flow rate/(L∙min-1) | 15 |

where PL, Vs and D represent laser power (W), scanning speed (mm/s) and laser spot size (mm), respectively. Thus, the EL in this work is calculated to be around 45.7 J/mm2.

The particle sizes of both powders were determined using a laser particle size analyzer (MALVERN, Mastersizer 2000, England). For investigating the phase compositions of both powders and coatings, an X-ray diffractometer (XRD, D/max 2550 VB3, Rigaku International Corporation, Japan) was utilized, employing Cu-Kα radiation at 40 kV and 40 mA. The XRD utilized a sampling interval of 0.01° and a scanning speed of 4°/min. To examine and analyze the coatings’ microstructure, an optical microscope (OM, ZEISS, Germany) and a scanning electron microscope (SEM, VEGA3 XM, TESCAN, China) equipped with energy dispersive spectroscopy (EDS) at an acceleration voltage of 15 kV were employed.

A Vickers hardness tester (HVS-1000A) with a diamond-shaped indenter was used to measure the microhardness of the cross-section (TR-ND surface) and surface (TR-RD) of the coatings, respectively, employing a test load of 200 g (1.98 N), denoted by HV0.2, with a dwell time of 15 s. Microhardness variation along depth from the surface to the bottom was measured at intervals of 200 μm on a cross-sectional coating sample using a HV-1000A Vickers microhardness tester under a 200 g load for 15 s. Each microhardness measurement test was repeated three times and then the average value was taken. The coating surface microhardness test pattern was set to 7×7, and the spacing between 2 indents was 100 μm, and the mapping area of each sample was 600 μm×600 μm. Nanoindentation (UNHTL+MCT, Switzerland) was used to test the microhardness of different phases in the coating under a load of 30 mN for 10 s. The wear resistance was tested on a high-speed ring block wear device (UMT TriboLab, BRUKER, Germany). Before wear resistance testing, the samples were sanded with sandpapers and then polished with polishing solution (particle size: 1.5 μm) to ensure that all the surfaces have the same roughness, and the Ra value of the metallographic surface is ~0.1 μm. Here Si3N4 with a HRC 60 hardness was used as friction counterpart to reciprocate on the coating surface. The parameters chosen for the wear test were listed as follows: the speed of 0.1 m/s, the test load of 5 N, the test distance of 5 mm, and the time of 0.5 h. Wear tests were performed at room temperature in an ambient air environment and under dry sliding conditions. The worn specimens were used to observe the wear profile on the worn surfaces and to calculate the wear loss volume using a SEM equipped with EDS and a laser confocal microscope (OLS40-CB). The wear amount is determined by assessing both the depth and width of the wear scars, and these parameters can be calculated using the following formula [34]:

where B is the width of wear scar; L is the length of wear scar; and R is the outer radius of wear ring. For error minimization, all measurements were conducted thrice to ensure accuracy and reliability.

3 Results and discussion

3.1 Microstructure

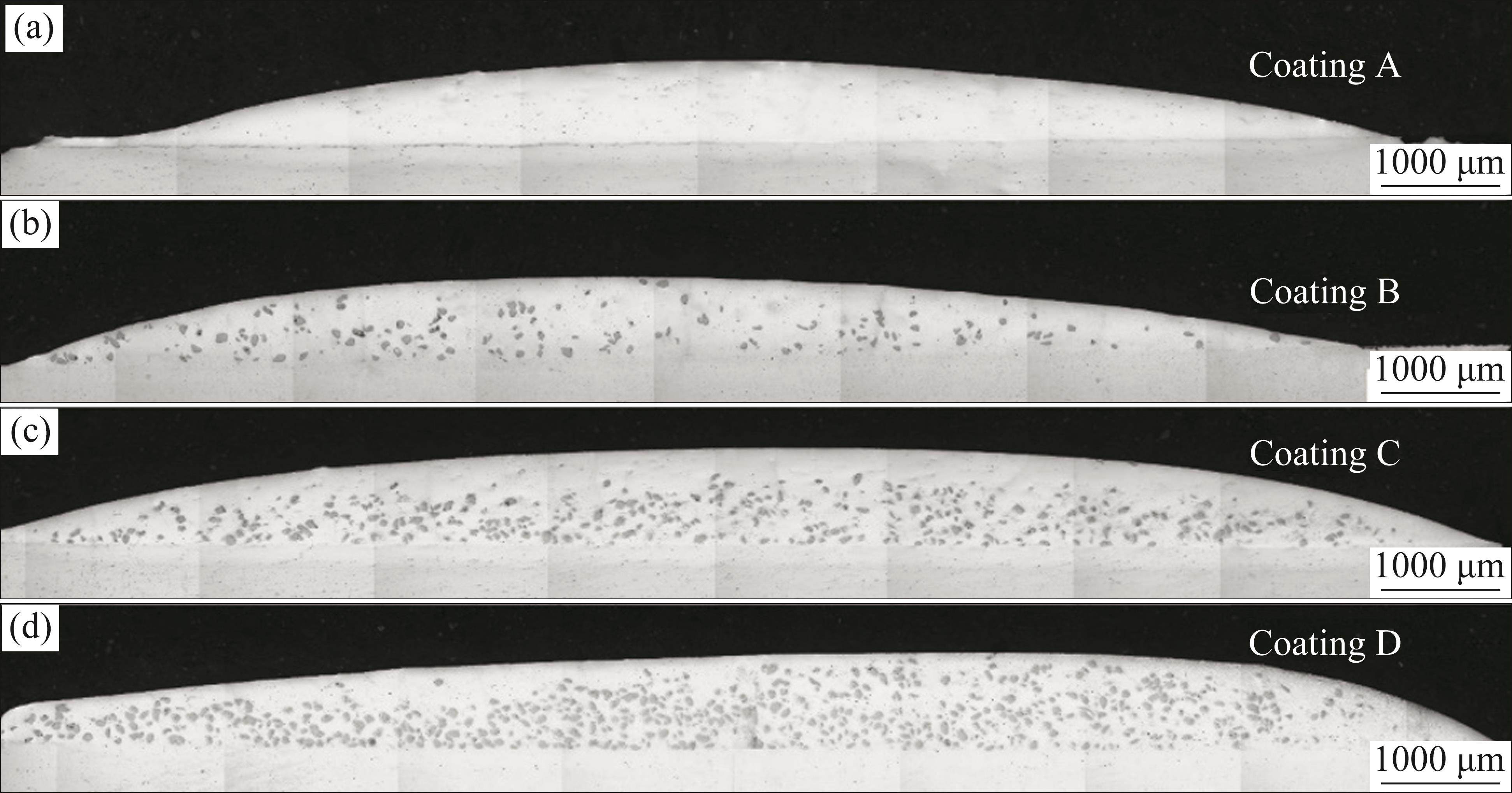

Figure 3 shows the cross-sectional images of laser cladded CoCrFeNiMo HEA-based coatings with different WC content (0, 10 wt.%, 20 wt.% and 30 wt.%). The thickness of all the coatings is measured by optical microscope and the value is around 1 mm. No defects such as obvious cracks, air holes, are observed in all the coatings. All the coatings/substrate interfaces are clear and straight, a good metallurgical bond with a low dilution rate is formed at interface. Due to the greater density of WC particles in the molten pool compared to the HEA matrix, the concentration of WC particles was found at the coating bottom. This phenomenon of a gradient distribution of the concentration of non-melted WC particles at different depths of the coating has also observed in previous reports [35, 36].

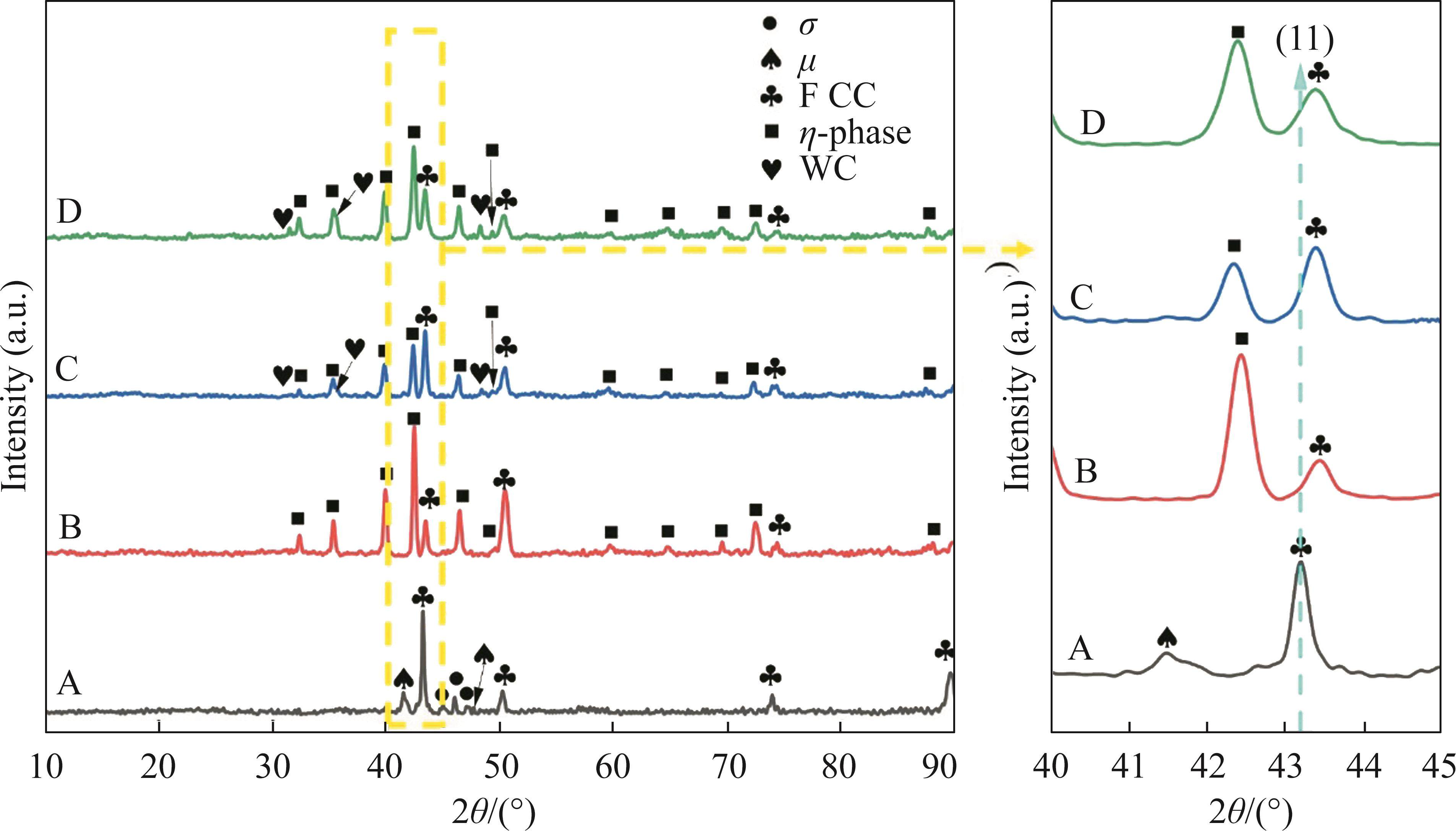

Figure 4 shows the XRD patterns of laser cladded WC/CoCrFeNiMo coatings. The A-coating mainly consists of the FCC phase (a=3.60263 Å, d=2.0790 Å (111)), the σ phase and the μ phase, which is essentially the same as the phase composition of the HEA powders as shown in Figure 1(f). It is noted that the σ' phase is not observed and the peaks of σ and μ phases are reduced in the coating compared to the powders. This should be related to the rapid cooling rate during the laser cladding process and the second phases are not conducive to precipitate. For the B, C, and D coatings, η-phase and FCC phases are the main phases and no distinct peaks of σ and μ phases are observed with the addition of WC particles. Some remaining WC particles are observed in both C and D coating, however, no W2C and W3C [30, 37] are observed, which is related to the inhibition of the decarbonization reaction of WC under the low linear energy density in this work [38]. η-phase is generally considered to be an M6C-M12C type carbide, which is easy to generate when carbon atoms content is low [39, 40]; thus, η-phase can be observed in the coatings when the low WC content was added in this work. M6C ((Fe, Cr, Ni, Co)3(W, Mo)3C) and M12C ((Fe, Cr, Ni, Co)6(W, Mo)6C) have similar crystal structures, and both of them can be categorized as η-phase. In previous researches [41], it has been widely recognized that M6C is composed of Fe3W3C. However, due to the extremely complexity of the possible reactions and products of the HEA-WC system during laser cladding, it is difficult to generalize to a defined single product. Moreover, based on the enthalpies of mixing of the elements as shown in Table 5 [42], the chemical affinity of molybdenum for carbon is much higher than that of other elements for carbon. Therefore, the bond of Mo and C is more readily compared to the other elements. Thus, the carbide type is significantly affected with the addition of Mo, which is verified by the enrichment phenomenon of Mo elements and various precipitated carbons as shown in Figures 5 and 6. Therefore, two M6C type carbides of Co3Mo3C (JCPDS card No. 65-7128) and Fe3W3C (JCPDS card No. 89-2579) are hypothesized to comprise the η-phase. Based on the enthalpies of mixing of the elements given in Table 5, it can be found that the enthalpy of mixing of each metallic element with carbon is much lower than that of mixing between metallic elements. Therefore, Mo element preferentially combines with C element to form carbide and consumes more Mo element, which makes the remaining Mo elements insufficient to form σ phase precipitates; thus, the amount of σ phase reduces with increasing WC content. It can be observed that the diffraction peaks of the FCC phase show a significant rightward shift with the addition of WC particles. For A coating, more Mo atoms are dissolved in the FCC phase, which leads to severe lattice expansion due to the large radius of Mo atom and can be described as the following formula [32]:

| Atom | Cr | Fe | Ni | Mo | W | C |

|---|---|---|---|---|---|---|

| Co | -4 | -1 | 0 | -5 | -1 | -42 |

| Cr | — | -1 | -7 | 0 | -1 | -61 |

| Fe | — | — | -2 | -2 | 4 | -50 |

| Ni | — | — | — | -7 | -3 | -39 |

| Mo | — | — | — | — | 0 | -67 |

| W | — | — | — | — | — | -60 |

where ε is lattice strain; a and a0 represent lattice constant and unit cell parameter of atom, respectively. In this work, the lattice strain value of A coating can be calculated as ε=2.3214% since a0=3.5238 Å [31] and a=3.6056 Å in HEA, proving the presence of severe lattice distortion in the FCC phase in the CoCrFeNiMo HEA coating by laser cladding. With increasing WC content, more amount of W atoms can be solid-solved into FCC phase, resulting in the increased lattice distortion, while the solid-solution of Mo amount is reduced in FCC phase and Mo is favor to form σ precipitates, resulting in the relaxion of lattice expansion and attenuation of lattice distortion, i.e., the lattice distortion of FCC phase is determined by the combined effect caused by the solid-solution of W and Mo atoms. Therefore, the diffraction peaks of the FCC phase shift to the right firstly and then shift to left with the increase of WC content, as shown in Figure 4.

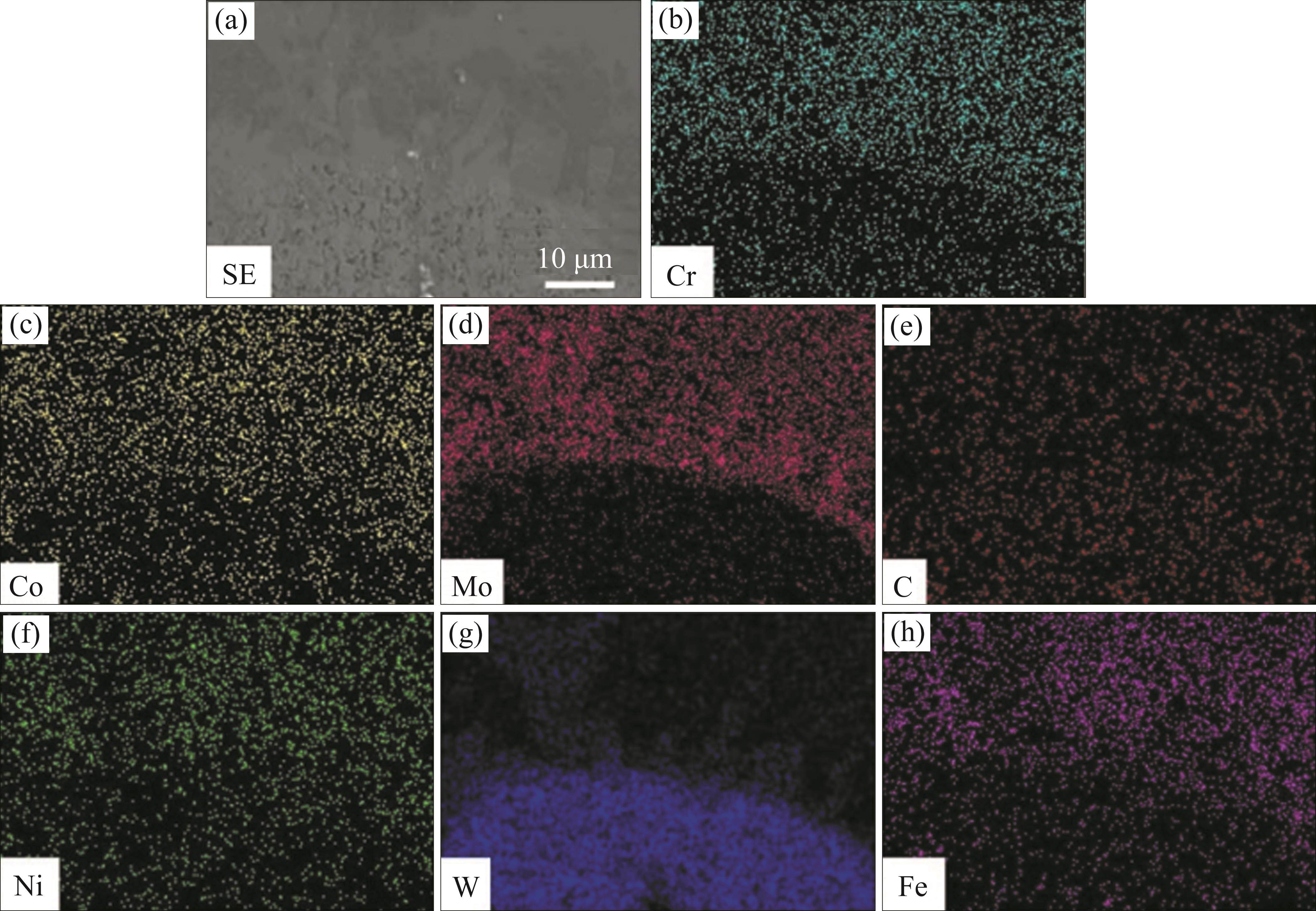

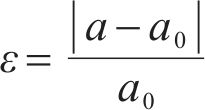

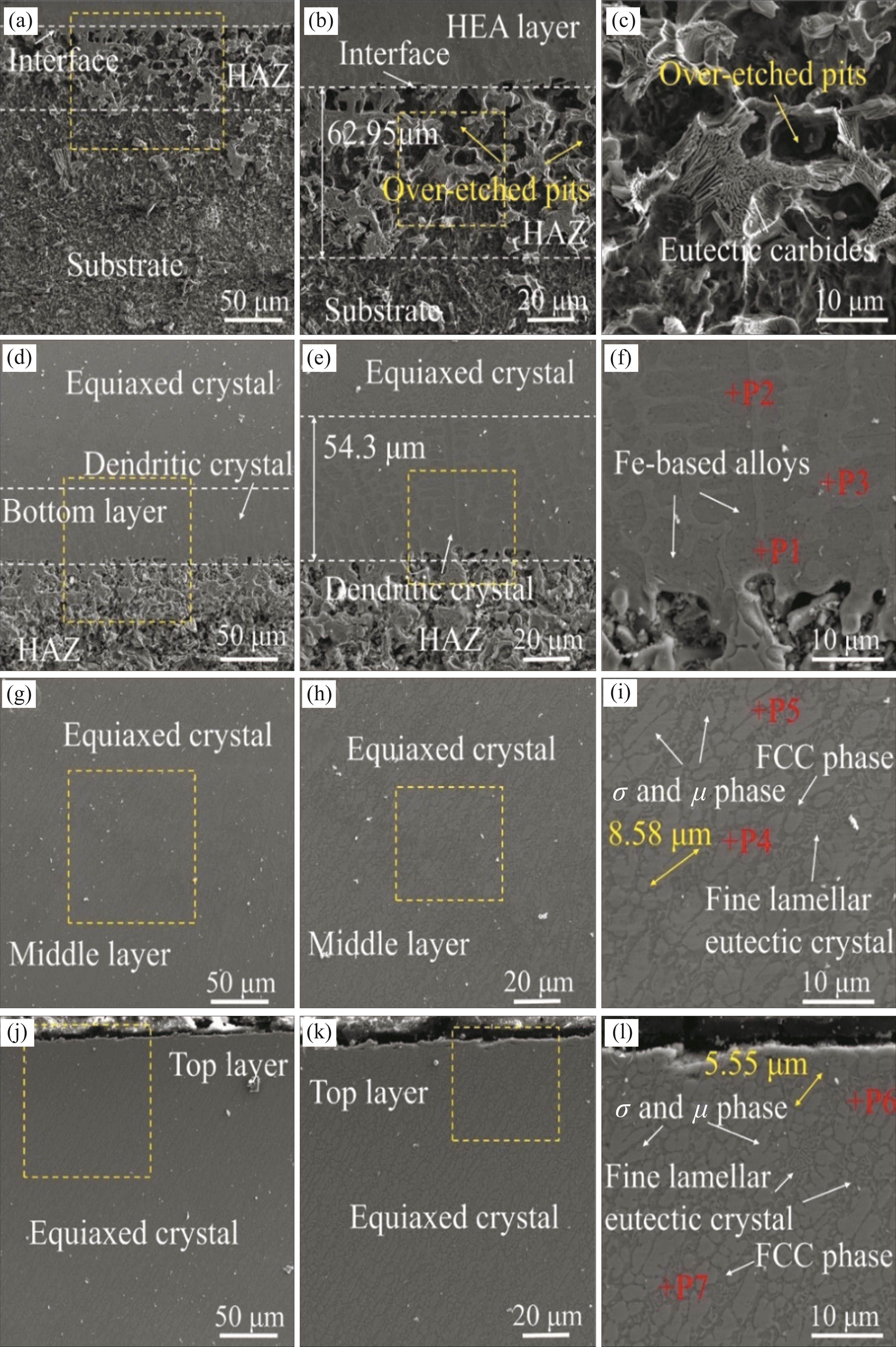

Figure 7 shows the cross-sectional SEM images of laser cladded CoCrFeNiMo coatings. The corresponding EDS point-scanning results and mapping-scanning elemental distribution in the middle part of A coating are presented in Table 6 and Figure 8, respectively. The cross-sectional morphology can be divided into four zones: substrate, heat-affected zone (HAZ), dendritic crystal zone and equiaxed crystal zone. The microstructure of the HAZ is significantly different from the substrate, and the thickness is about 62.95 μm, as shown in Figures 7(a)-(c). During the laser cladding process, different degrees of austenitization and composite carbide dissolution of substrate occur, which is related to the distance from the interface due to the intense thermal effect by the laser. Owing to the extremely fast cooling rate after the laser leaves, some carbides remain in the austenite. Therefore, cryptocrystalline martensite, massive eutectic carbides, granular secondary carbides (which forms over-etched pits when it corrodes) and residual austenite form in the heat-affected zone. The cross-sectional microstructure of the CoCrFeNiMo coating transitioned from a dendritic to an equiaxed crystal structure, as illustrated in Figures 7(d)-(f). This shift in microstructure is primarily governed by the ratio of temperature gradient (G) to solidification rate (R), i.e., denoted as G/R [43]. In the coating, the G/R value near the bottom region surpasses that of the top region. Consequently, the lower portion of the coating exhibits a dendritic crystal structure, whereas the upper portion displays an equiaxed crystal formation. During laser cladding, epitaxial growth of dendrites occurs perpendicular to the interface because the temperature gradient is perpendicular to the interface and dendrites usually grow in the opposite direction of the temperature gradient. Table 6 shows that the dendrites near the interface are composed of Fe-based alloys containing some high-entropy alloying elements, and the HEA alloying elements content, such as Co, Cr, Ni and Mo, gradually increases with increasing distance from the interface.

| Point | Fe | Co | Cr | Ni | Mo |

|---|---|---|---|---|---|

| P1 | 65.81 | 11.55 | 10.49 | 9.85 | 2.30 |

| P2 | 52.93 | 15.67 | 12.76 | 14.60 | 4.04 |

| P3 | 38.36 | 9.57 | 20.50 | 7.74 | 23.83 |

| P4 | 17.55 | 23.35 | 22.93 | 14.92 | 21.25 |

| P5 | 19.12 | 24.62 | 22.20 | 19.07 | 14.99 |

| P6 | 16.81 | 22.65 | 24.46 | 14.35 | 21.73 |

| P7 | 20.02 | 25.58 | 19.62 | 22.52 | 12.26 |

Figures 7(g)-(l) show microstructures at middle and top part of CoCrFeNiMo coating. Similar microstructures composed of equiaxed crystals (σ-phase) and intergranular eutectic tissues (FCC+σ-phase) distributed between the crystals are found to exist at these two parts. According to the well-known electron‐hole theory, alloys are prone to precipitate σ-phase when the average electron hole number is greater than 2.50 [44]. In this work, Cr and Mo elements have larger electron hole numbers, which is favor to the form σ-phase. According to the following formula [32]:

where

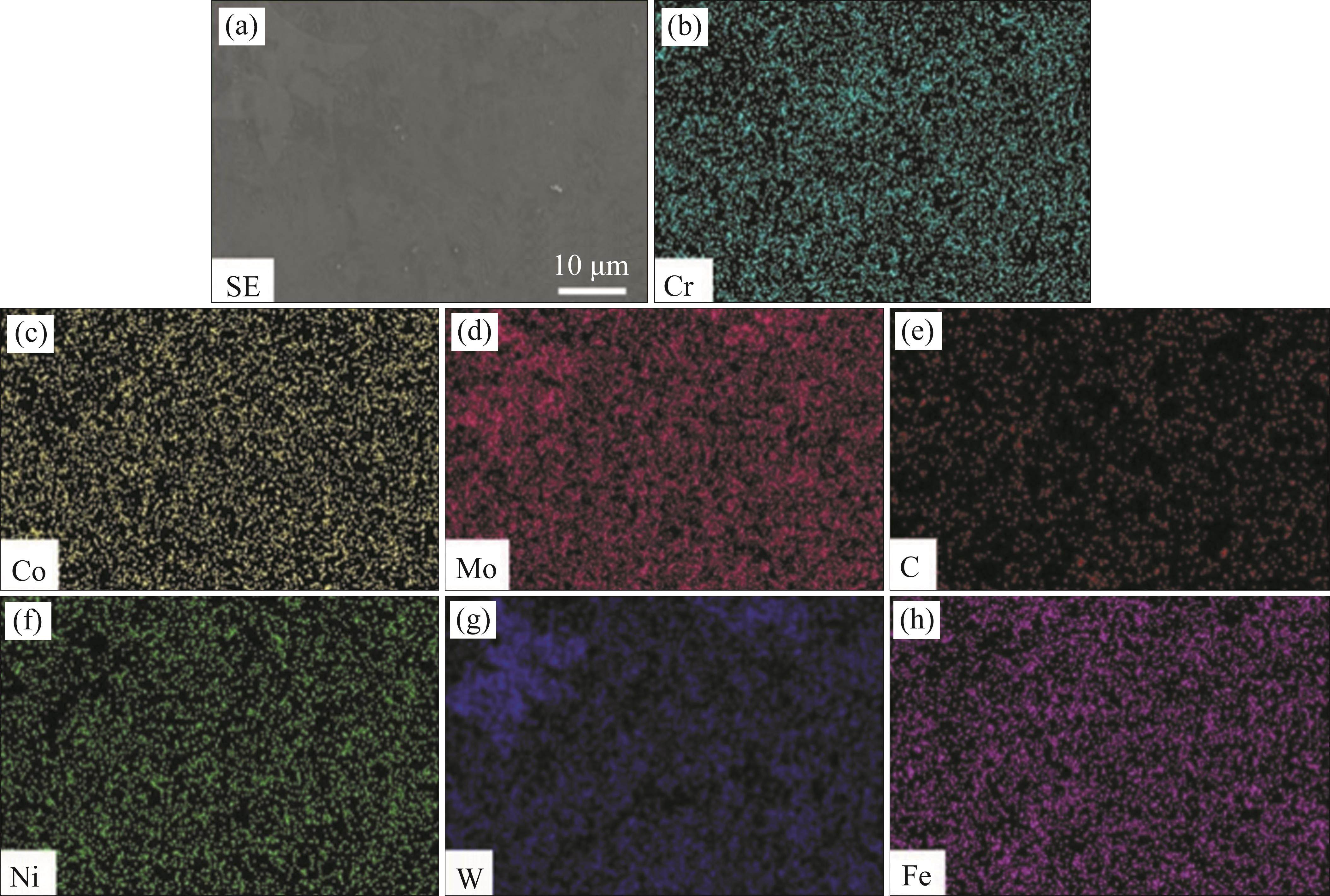

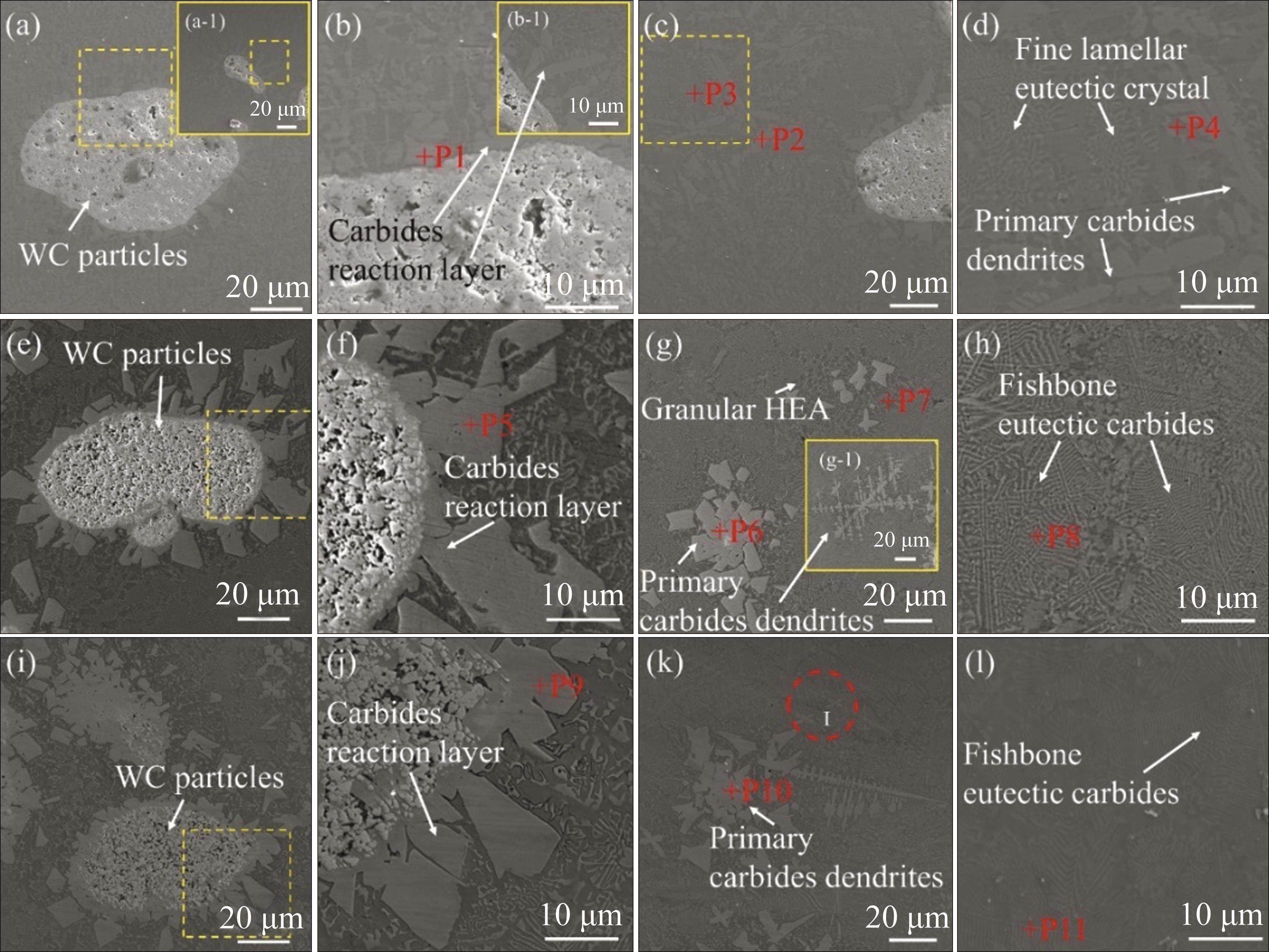

Figure 9 shows the cross-sectional microstructure of WC/CoCrFeNiMo composite coatings at middle part with different WC contents, and the related EDS results are presented in Table 7. With the addition of WC, the microstructure of B, C and D coatings becomes complex, and the composite coatings are composed of incompletely fused WC particles, primary crystals, eutectic structures, and massive crystals growing around the WC particles. Combined Figures 5, 6 and Table 7, the coatings are composed of FCC containing Fe, Co and Ni elements, and carbide containg Mo and W elements. It is observed that the W amount in FCC increases and Mo amount decreases with increasing WC content, which is consistent with the analytical results of the shift of the FCC diffraction peaks. Table 7 also shows that the primary crystals, the massive crystals around the WC particles are composed of M6C carbides, while the eutectic structures are composed of FCC + carbides. Some researches showed that the microscopic morphologies of M6C depends on the W atoms content at the solidification front [45]. During laser cladding, the W atomic content near the incompletely melted WC particles in the melt pool is around 50%, and M6C tends to grow as massive crystals under this condition. When the W atomic content decreases to above the eutectic threshold, the incipient dendritic M6C crystals precipitate. Further decreasing W atomic content, M6C/FCC eutectic forms. When the W atomic content is below 0.37%, the FCC solid solution forms in the remaining region. Similar microstructure was observed in PENG et al’s work [41].With the WC content increasing, more released carbon atoms from WC are favor to the nucleation and growth of primary carbide crystals and the eutectic structures. Thus, the primary carbide crystals gradually become denser and larger (Figures 9(c), (g), (k)), the eutectic microstructure changes from fine lamellar to fishbone eutectic (Figures 9(d), (h), (l)), and the reactive layer becomes thicker and more massive precipitates grow epitaxially around it (Figures 9(a), (e), (i)). The formation process for each precipitate is different and explained as below.

| Point | C | Cr | Fe | Co | Ni | Mo | W |

|---|---|---|---|---|---|---|---|

| P1 | 30.07 | 14.57 | 11.74 | 12.70 | 9.65 | 19.41 | 1.87 |

| P2 | 30.84 | 14.28 | 13.38 | 14.13 | 12.99 | 13.38 | 0.98 |

| P3 | 27.68 | 14.85 | 15.53 | 15.65 | 15.87 | 9.74 | 0.67 |

| P4 | 27.34 | 17.91 | 16.16 | 18.86 | 14.31 | 5.32 | 0.10 |

| P5 | 44.99 | 8.90 | 6.90 | 8.11 | 5.27 | 19.29 | 6.55 |

| P6 | 43.28 | 9.97 | 7.54 | 8.75 | 6.16 | 18.53 | 5.78 |

| P7 | 29.90 | 12.80 | 15.82 | 17.18 | 16.04 | 6.97 | 1.28 |

| P8 | 35.76 | 12.85 | 12.23 | 12.66 | 11.13 | 11.96 | 3.41 |

| P9 | 42.30 | 9.04 | 7.33 | 10.04 | 7.23 | 17.11 | 6.96 |

| P10 | 40.43 | 10.69 | 9.06 | 11.58 | 9.35 | 13.02 | 5.87 |

| P11 | 32.65 | 12.25 | 13.54 | 14.54 | 13.63 | 10.42 | 2.96 |

The melting point of WC particles (2720 ℃) is higher than that of HEA particles [46]. The HEA powders melt firstly and a large number of incompletely melted WC particles are present in the molten pool during the laser cladding process. The C and W atoms are enriched around the residual WC particles, owing to the short duration of the molten pool. During solidification, these C and W atoms react with the HEA atoms in the molten pool to precipitate carbide reaction layer, which grows epitaxially with the residual WC particles surface as non-uniform nucleation sites. Massive (Figures 9(f), (j)) or dendritic (Figures 9(b)-(1)) carbide crystals grow outward based on the reaction layer when high content of WC particles transformed into liquid state. Under such a condition, massive blocky carbide precipitates are formed in the reaction-based layer, and the growth of carbide grains at this point is limited by its orientation relationship with WC [47]. The thickness of the reaction layer depends on the temperature and time of the interfacial reaction [48] and WC content. Ceramic materials (WC) have a higher absorption of laser light and poorer thermal conductivity compared to metals, more energy is stored in the composite coating containing high WC content [49], which results in the slow cooling rate of molten pool and long reaction time. Therefore, massive blocky carbide precipitates increase with increasing WC content. The interfacial reaction layer indicates good wettability between HEA and WC particles, which plays a very important role in their properties for composite coating.

Primary carbide dendrites have a regular shape indicating that they nucleate from the liquid state rather than the solid state. Some of the WC particles fully melted in the molten pool, especially the fine particles, as its relative surface area is larger and it absorbs more specific energy of the laser light. These fully melted C and W atoms accumulated and in-suit reacted with the HEA atoms to form primary carbide crystals in the molten pool through charge migration and atomic transfer [50]. During the precipitates growth process, the precipitates grow planarly and form a blocky-shaped phase when the front of the solid-liquid interface possesses a positive temperature gradient, as shown in Figure 9(g). The precipitates grow dendritically and form a dendritic-shaped phase when negative temperature gradient exists at the solid-liquid interface, as shown in Figures 9(g)-(1). LIU et al [47] also noted that primary carbide grains were formed by an inclusion reaction and a ring of granular HEA supersaturated solid solution was always formed around the primary polyhedral carbides, which was resulted from the fact that the excess primary polyhedral carbides hindered the subsequent eutectic reaction during the solidification of the molten pool [51].

A small amount of diffused C atoms reacts with the HEA atoms in the molten pool. The eutectic microstructure of carbide + FCC is obtained after the primary carbide crystals are precipitated and the molten pool temperature is lowered to the eutectic point. The special fishbone-like eutectic microstructure are formed, and the carbides are characterized by strong eutectic growth on microcrystalline plane, and usually exhibit eutectic growth of dendritic clusters on radially radiating microcrystalline plane [41, 52]. The primary carbides can provide nucleation sites for carbide in the eutectic reaction, and the eutectic carbides grow directly along the primary carbide crystal surface, as shown in region Ⅰ of Figure 9(k).

3.2 Microhardness

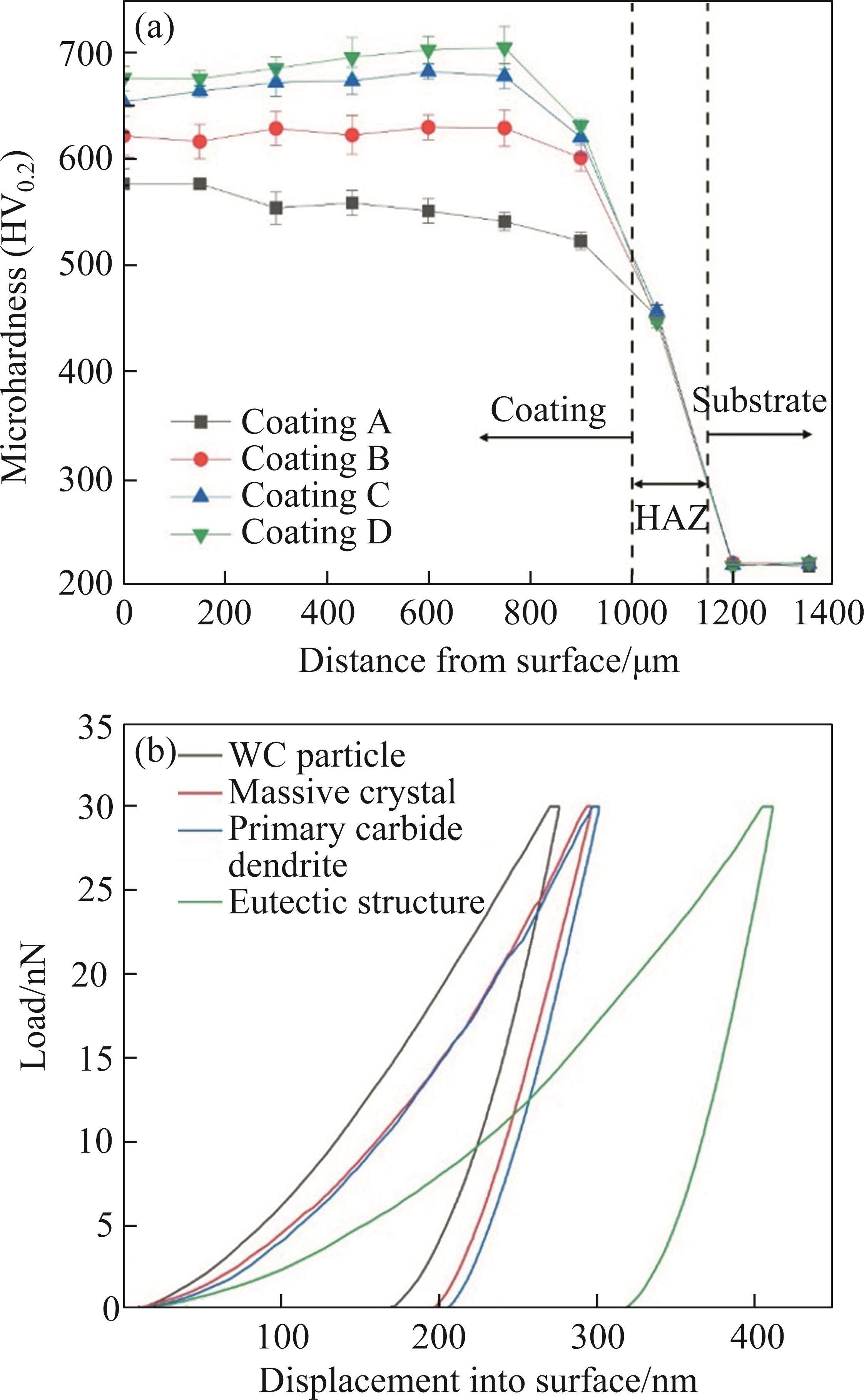

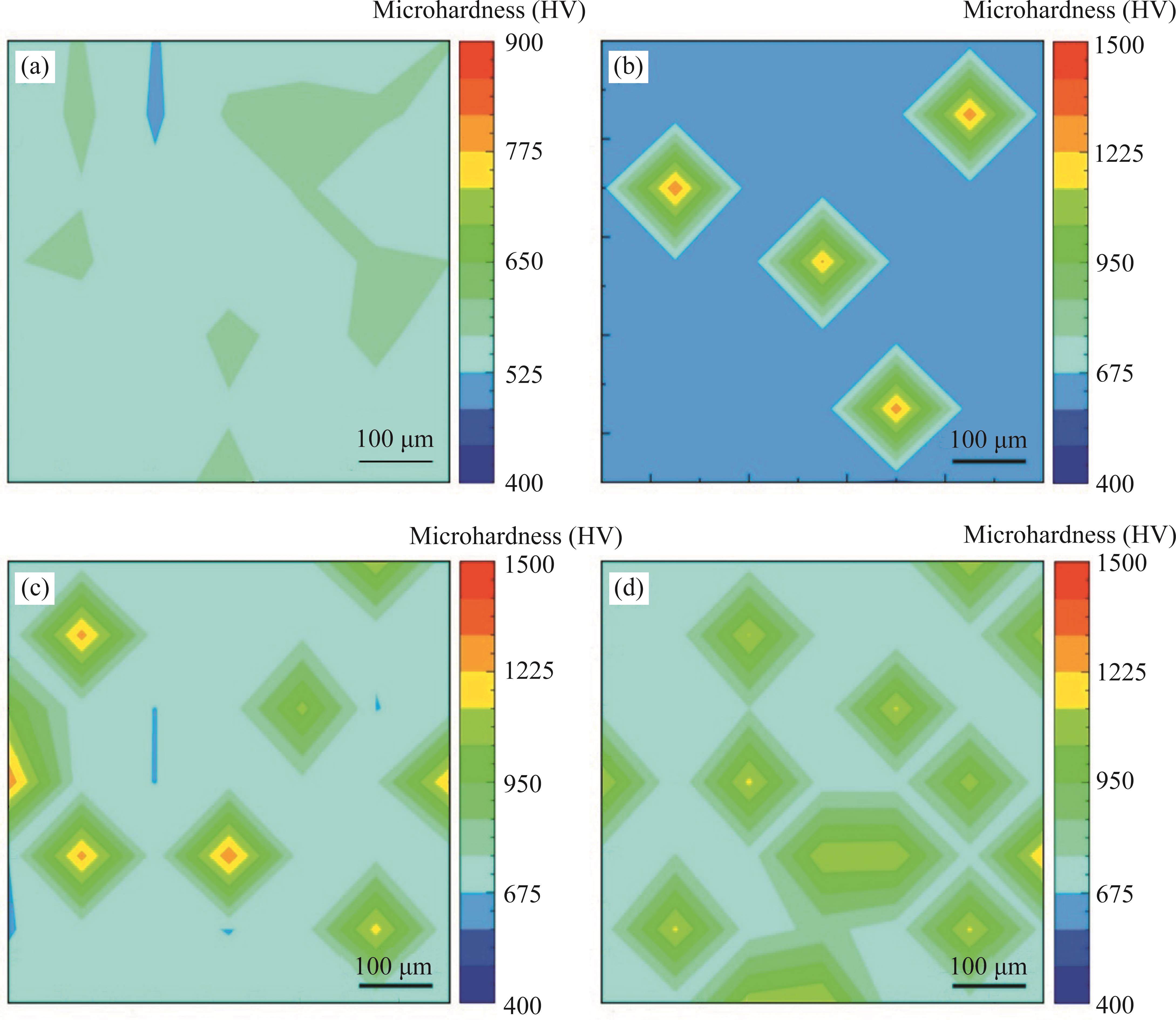

Microhardness at different positions of the coatings was tested and the results were shown in Figure 10(a). Based on the change in microhardness value, the cross-sections can be divided into three zones, which are corresponded to the coating, heat affected zone (HAZ) and 45 steel Cr12MoV substrate, respectively. The microhardness distribution obeys the following rules: coating>HAZ>substrate. Due to grain refinement and carbides precipitation in the heat-affected zone during laser cladding, the microhardness of HAZ (HV0.2 515) rises significantly compared to substrate. Meanwhile, it is noted the microhardness at the heat-affected zone is dramatically lower than that within the coatings, which is related to the formation of low-hardness Fe-based alloy dendritic crystals at the interfaces. The microhardness of WC/CoCrFeNiMo composite coatings is higher than that of CoCrFeNiMo coating, the microhardness value of the coating is gradually improved with increasing WC content. When the added WC content is 30% (D coating), the maximum composite coating microhardness of HV0.2 689.7 is obtained, which is 23.2% and 215.9% higher than that of the CoCrFeNiMo coating (HV0.2 559.8) and Cr12MoV substrate (HV0.2 218.3), respectively. The microhardness of WC/CoCrFeNiMo composite coatings achieved in this work is also much higher than that of the WC/CoCrFeNi composite coatings prepared by laser cladding or plasma cladding with a hardness value ranged from HV 200 to HV 580 varying with WC content (Table 8). With the addition of WC particles, some WC particles can be melted and free W and C atoms dissolute into FCC phase, which attributes to the increment of coating microhardness. Meanwhile, the precipitation of various forms of hard and brittle carbides and the remaining WC particles play as the second phase strengthening effect on the improvement of mechanical property of composite coatings. Nanoindentation tests were carried out on MMC coatings with 30 wt.% WC content to measure the microhardness of different microstructures, and the results were shown in Figure 10(b). The decrease in the maximum indentation depth (Hmax) indicates the higher microhardness of the corresponding phase. WC particles possess the highest microhardness, and the microhardness value of WC particles, massive crystals, primary dendrite crystals, eutectic structures are 23.1 GPa (HV 2137.9), 21.8 GPa (HV 2022.5), 20.3 GPa (HV 1884.2) and 9.4 GPa (HV 868.5), respectively. It is noted that the microhardness of the massive and primary dendritic crystals is essentially the same, which is due to the same M6C structure of these two microstructures. Microhardness mapping was carried out to investigate the microhardness distribution of each coating, and the results were shown in Figure 11. The microhardness around the residual WC particles is higher than that in other areas of the coating, which is consistent with the results of the microhardness of each phase measured by nanoindentation. On the whole, the overall distribution of coating microhardness is relatively uniform, which is related to the uniform distribution of WC particles in the coating.

| Composition | Preparation method | Microhardness | Wear rate/ (mm3·N-1·m-1) | Friction coefficient | Ref. |

|---|---|---|---|---|---|

| FeCoCrNi+2.5 wt.%WC | Laser cladding | HV ~360 | — | — | [37] |

| FeCoCrNi+5.0 wt.%WC | HV ~200 | — | |||

| AlCoCrFeNi+10 wt.%WC | Laser cladding | HV 577 | — | — | [53] |

| FeCoCrNi+20 wt.% WC | Laser cladding | — | 0.7 × 10-5 | 0.29 | [29] |

| FeCoCrNi+20 wt.% WC | Plasma cladding | — | 8.29 × 10-5 | 0.5-0.9 | |

| FeCoCrNi+20 wt.% WC | Plasma cladding | HRC (41.7±3.6) | ~3.7×10-6 | 0.69 | [41] |

| FeCoCrNi+40 wt.% WC | HRC (53.2±2.0) | ~1×10-6 | 0.45 | ||

| FeCoCrNi+60 wt.% WC | HRC (59.6±2.8) | 3.27×10-7 | 0.42 | ||

| FeCoCrNi+70 wt.% WC | HRC (61.9±1.7) | 8.57×10-7 | 0.35 | ||

| CoCFerNiMn+10 wt.% WC | Laser cladding | HV 193.6 | ~1.2×10-4 | 0.36 | [45] |

| CoCFerNiMn+20 wt.% WC | HV 335.2 | ~5×10-5 | 0.34 | ||

| CoCFerNiMn+30 wt.% WC | HV 488.1 | 2.37×10-6 | 0.28 | ||

| CoCFerNiMn+40 wt.% WC | HV 516.8 | 3.49×10-6 | 0.36 |

3.3 Wear property

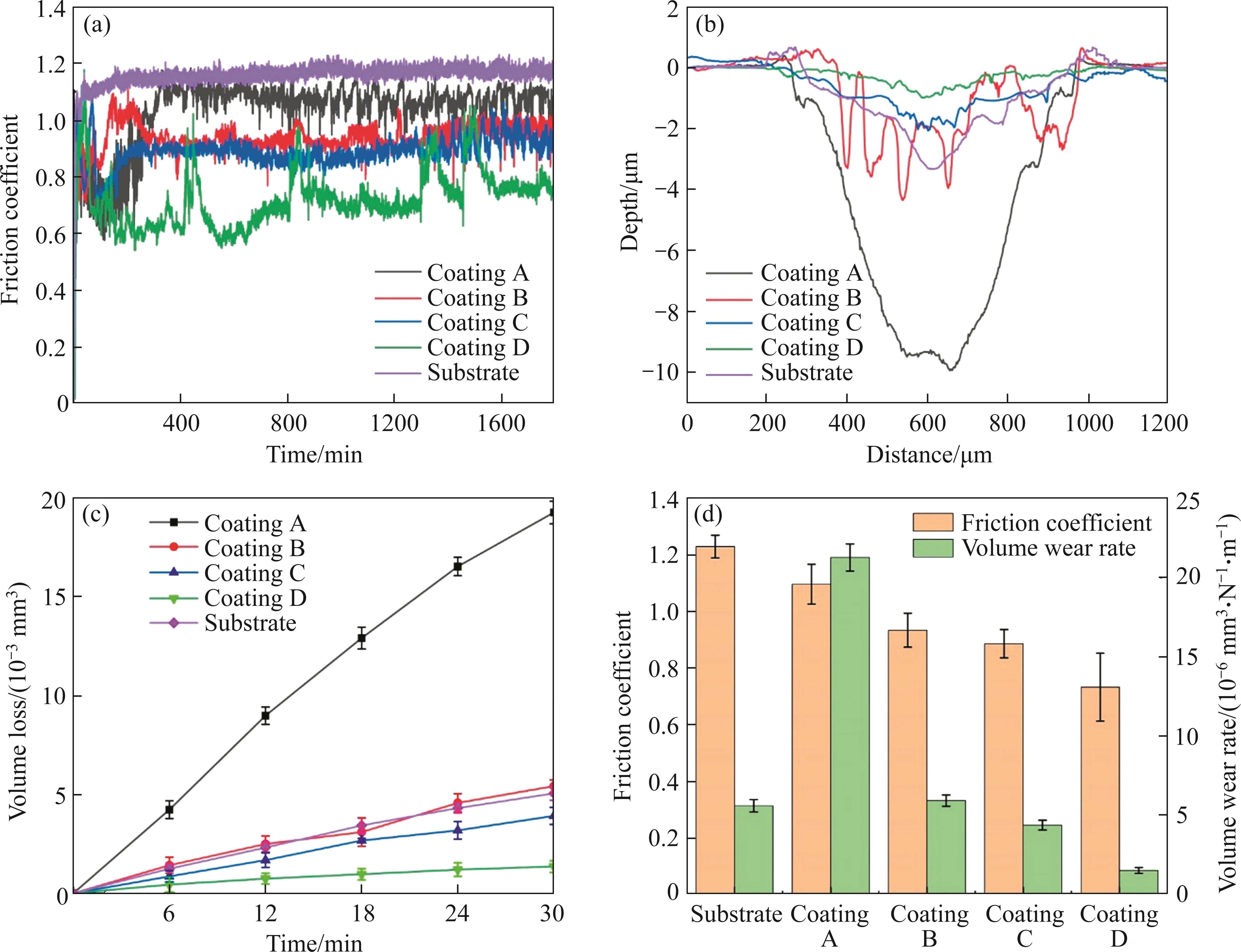

Figure 12(a) shows the friction coefficients curves of the coating under the same condition. The friction coefficients can be acquired when the friction coefficients curves tended stable, and the average friction coefficients corresponding to each coating samples are shown in Figure 12(d). Due to the large adhesion force resulting in the small contact area between the wear couple and the coating [54], in the early friction period, the friction coefficients of all the specimens increases rapidly. The friction coefficients of the Cr12MoV substrate and cladding coatings are stable when the testing time reaches to 300 s. The average friction coefficients of all the coatings (0.7215-1.035) are lower than that of the substrates (1.161). With increasing WC content, the average friction coefficients of WC/CoCrFeNiMo coatings decreases significantly, which follows the opposite trend comparing to the coating microhardness. The wear rate of the composite coatings prepared in this work is slightly lower than that of the WC/CoCrFeNi composite coatings prepared by laser cladding or plasma cladding (Table 8). It is generally accepted that metals with high hardness have lower frictional resistance [55], which is consistent with the results in this work. Significant wide range fluctuations are observed in the friction coefficient profile of coating D, which can be interpreted as particle shedding in the 30 wt.%WC/CoCrFeNiMo composite coating with high WC content, and a similar phenomenon has been observed in previous studies [56]. With increasing WC content, the percentage of the M6C phase increases, which effectively improves the coating micro-cutting resistance to Si3N4 balls and reduces the wear rate of the coating. It demonstrated that the coating layer, especially composite coating, shows the best friction-reduction property at the stable friction stages.

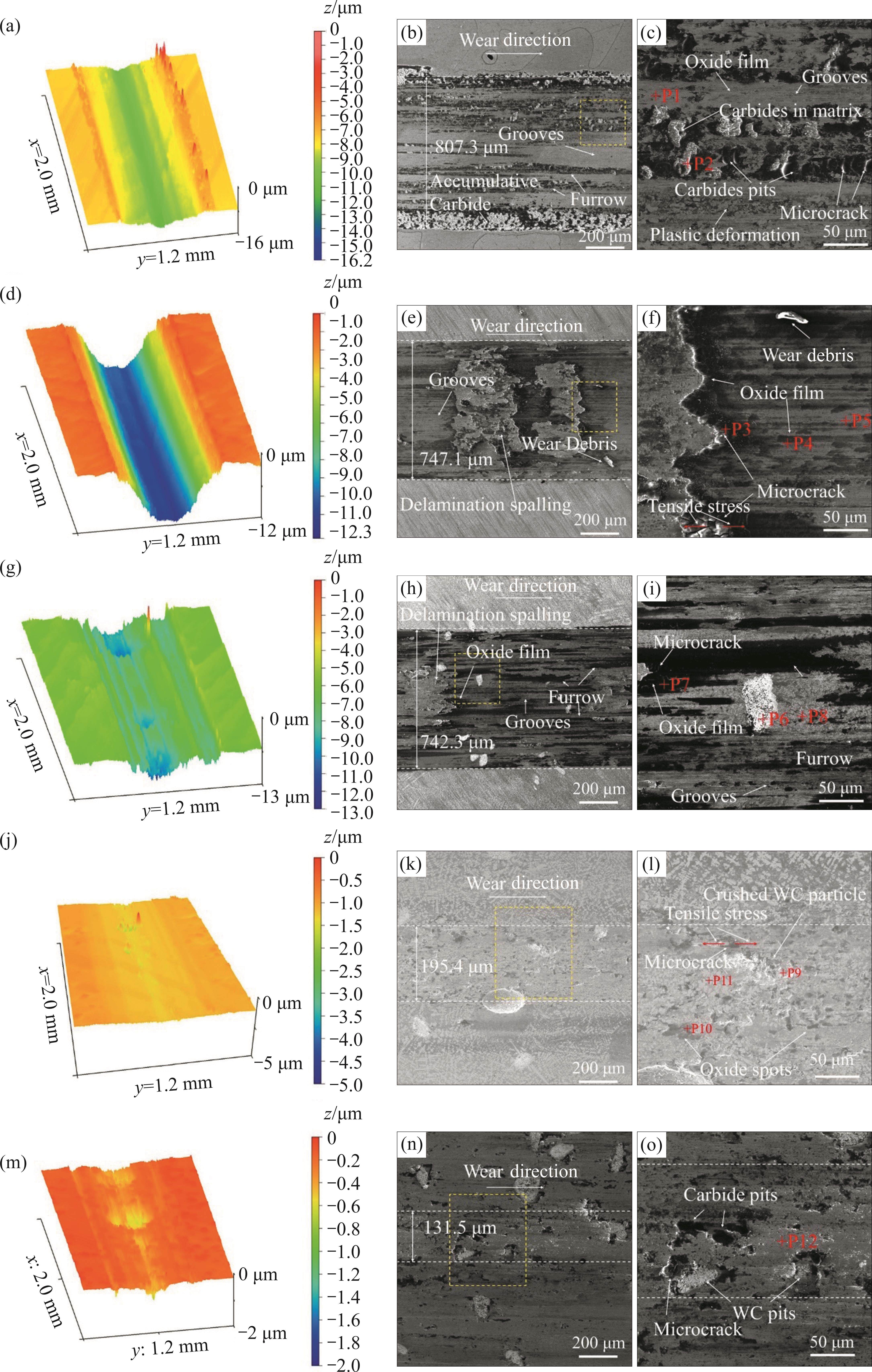

Figure 12(b) shows the wear profile of the substrate and coatings, and the corresponding volume loss vs time curves, and specific wear rate are shown in Figures 12(c) and (d), respectively. The worn morphologies of substrate and different coatings obtained by SEM and laser confocal microscope are shown in Figure 13. The worn surface width of substrate, A coating, B coating, C coating and D coating measured by SEM is about 807.3, 747.1, 742.3, 195.4 and 131.5 μm, respectively. The width and height of the abraded area of the substrate are larger than that of the coatings. Meanwhile, with increasing WC content, the width and height of the abraded area decrease gradually (Figure 12(b)). While all the volume loss of the coatings possess a low value compared to that of substrate, and it decreases significantly with increasing WC content (Figure 12(c)), which can also be attributed to the increase in hardness [57]. The volume wear rate of the substrate, A coating, B coating, C coating and D coating is 5.61×10-6, 21.28×10-6, 5.94×10-6, 4.39×10-6 and 1.53×10-6 mm3/(N·m), respectively (Figure 12(d)). With increasing WC particles added into CoCrFeNiMo coatings, the volume wear rate decreases gradually. It is noted that the volume wear rate of Cr12MoV substrate is lower than that of A and B coatings. This can be attributed to the friction-reducing effect of carbides in the substrate and the enhancement of wear resistance by the dense, continuous oxide formed on the steel substrate during friction process [58]. Figures 13(a), (d), (g), (j) and (m) show the profiles of the wear scans. The results also depicts that the worn depth of the WC/CoCrFeNiMo composite coating with 30 wt.% WC content is minimum, and the worn depth of the substrate is maximum. According to the morphologies and profiles of the wear scans, the WC/CoCrFeNiMo composite coating with 30 wt.% WC content shows the best tribological properties.

For the worn morphology of substrate shown in Figures 13(b) and (c), it can be found that large quantities of carbides are gathered at the edges of wear marks, a similar phenomenon was also observed in GONG et al’s study [59]. Grooves with numerous carbide pits, microcracks and furrows occur with severe wear process, and plastic deformation in some areas is found. From the EDS results as shown in Table 9, significant oxidation occurs during friction process; a dense and continuous layer consisting mainly of Fe2O3 forms at worn surface, which is tightly bonded to the substrate. When the oxide layer peels off from the substrate, hard carbides protrude out and grooves form on the worn surface. The furrow is the typical characteristic of abrasive wear, and debris was the typical characteristic of adhesive wear [60]. It is indicated the wear mechanisms of substrate included adhesive wear, peeling wear, abrasive wear and oxidation wear. Figures 13(e)-(o) show the worn morphologies of the laser cladding coatings. Coating A exhibits clear signs of delamination spalling, with severe plastic deformation observed in the upper layer and grooves in the lower layer in the sliding direction. Large numbers of oxide and some wear debris can be seen in the worn surface of CoCrFeNiMo coating, indicating that the wear mechanisms of CoCrFeNiMo coating included oxidation wear and adhesive wear. Weaker delamination spalling is observed on the worn surface of coating B than on coating A. It can be seen that there are some furrows with oxide and little deformation existed on the surface in the worn surface of 10 wt.% WC/CoCrFeNiMo composite coating, indicating that the wear mechanisms are abrasive wear and oxidation wear. When the WC content increases to 20 wt.%, the mixed mechanisms of abrasive wear, adhesive wear and slightly oxidation wear occur on the worn surface. Further increasing the WC content to 30 wt.%, WC pits and carbide pits are found on the worn surface, indicating that the wear mechanisms of the laser cladding 30% WC/CoCrFeNiMo composite coatings are abrasive wear and spalling wear. The wettability between HEA and WC significantly affects the wear properties of the coating. It is generally believed that if the wettability between the two materials is poor, no metallurgical bond is formed or the bonding effect is inferior, or if the reaction between the two materials is excessive to form a large number of brittle intermetallic compounds, which increases the tendency to crack due to residual stresses caused by different coefficients of thermal expansion, the composite material will not perform as expected [61-64]. Despite this, D coating has the lowest average coefficient of friction and wear rate with the best wear resistance, which is attributed to the increase in microhardness due to the increasing amount of WC particles and carbides.

| Point | C | O | Cr | Fe | Co | Ni | Mo | W | V |

|---|---|---|---|---|---|---|---|---|---|

| P1 | 19.97 | 15.18 | 7.48 | 57.33 | — | — | 0.04 | — | 0.00 |

| P2 | 29.01 | 13.67 | 12.89 | 44.12 | — | — | 0.17 | — | 0.15 |

| P3 | — | 65.14 | 6.87 | 11.18 | 5.94 | 5.46 | 5.40 | — | — |

| P4 | — | 43.41 | 11.45 | 14.52 | 10.94 | 9.73 | 9.94 | — | — |

| P5 | — | 20.15 | 14.75 | 22.98 | 15.23 | 15.02 | 11.85 | — | — |

| P6 | 38.00 | 11.62 | 3.19 | 5.08 | 19.18 | 3.47 | 1.86 | 17.61 | — |

| P7 | 12.04 | 51.06 | 6.80 | 11.90 | 6.48 | 4.89 | 6.23 | 0.60 | — |

| P8 | 19.01 | 34.52 | 9.07 | 15.69 | 7.70 | 6.93 | 6.63 | 0.46 | — |

| P9 | 34.60 | 19.59 | 6.44 | 7.50 | 6.55 | 3.87 | 5.82 | 15.62 | — |

| P10 | 12.02 | 64.30 | 4.21 | 6.11 | 5.16 | 3.36 | 3.17 | 1.67 | — |

| P11 | 34.11 | 6.27 | 9.51 | 12.21 | 9.18 | 5.10 | 14.51 | 9.11 | — |

| P12 | 18.64 | 6.65 | 15.46 | 14.59 | 15.04 | 11.15 | 16.25 | 2.22 | — |

4 Conclusions

WC/CoCrFeNiMo high-entropy alloy (HEA) composite coatings were successfully prepared on Cr12MoV steels surface by laser cladding, and the effects of WC content on the microstructure, microhardness and wear property of the composite coatings were analyzed in detail. The following conclusions were drawn from this work.

1) The microstructures of WC/CoCrFeNiMo composite coatings are mainly consisted of large numbers of carbides with four main types: primary carbide crystals, eutectic structures, massive crystals growing along the periphery of the remaining WC particles and incompletely fused WC particles. With the addition of WC content, σ and μ phases are reduced while eutectic structures of carbide + FCC are formed compared to CoCrFeNiMo coating.

2) The microhardness of coating is gradually improved with the increase of WC content. Due to solid solution strengthening and second phase strengthening effect, the maximum microhardness value of HV0.2 689.7 is obtained when the added WC content is 30 wt.%, which is 23.2% and 215.9% higher than that of the CoCrFeNiMo coating (HV0.2 559.8) and Cr12MoV substrate (HV0.2 218.3), respectively.

3) With increasing WC content, the average friction coefficients of WC/CoCrFeNiMo coatings decreases significantly, and the minimum friction coefficient of 0.72 is obtained for the composite coating when 30 wt.% WC is added. The wear mechanisms of the 30 wt.% WC/CoCrFeNiMo composite coatings are abrasive wear and spalling wear due to their high microhardness.

Evolution of carbides in cold-work tool steels

[J]. Materials Characterization, 2015, 107: 376-385. DOI: 10.1016/j.matchar.2015.08.001.Effects of picosecond laser repetition rate on ablation of Cr12MoV cold work mold steel

[J]. Applied Surface Science, 2017, 409: 403-412. DOI: 10.1016/j.apsusc.2017.02.236.Microstructure evolution and abrasive wear behavior of D2 steel

[J]. Wear, 2015, 328-329: 206-216. DOI: 10.1016/j.wear.2015.02.019.Prolonging the service life of shot-blaster blades made from high chromium cast iron

[J]. Wear, 1990, 135(2): 391-402. DOI: 10.1016/0043-1648(90)90038-C.Corrosion resistance of carbon ion-implanted M50NiL aerospace bearing steel

[J]. Progress in Natural Science: Materials International, 2017, 27(5): 615-621. DOI: 10.1016/j.pnsc.2017.07.003.Comparison of CoCrFeNi coatings prepared via high-speed laser cladding and normal laser cladding on microstructure and properties

[J]. Intermetallics, 2023, 153: 107795. DOI: 10.1016/j.intermet.2022.107795.Experimental study of laser cladding process and prediction of process parameters by artificial neural network (ANN)

[J]. Journal of Central South University, 2022, 29(10): 3489-3502. DOI: 10.1007/s11771-022-5170-y.Experimental study on mechanism of influence of laser energy density on surface quality of Ti-6Al-4V alloy in selective laser melting

[J]. Journal of Central South University, 2022, 29(10): 3447-3462. DOI: 10.1007/s11771-022-5135-1.Beam shaping technology and its application in metal laser additive manufacturing: A review

[J]. Journal of Materials Research and Technology, 2023, 26: 4606-4628. DOI: 10.1016/j.jmrt. 2023.08.037.Model heat source using actual distribution of laser power density for simulation of laser processing

[J]. Journal of Central South University, 2022, 29(10): 3277-3293. DOI: 10.1007/s11771-022-5133-3.Improvement of laser welded TC4/CFRTP joint strength by combination of surface modification of MAO and laser texturing

[J]. Thin-Walled Structures, 2024, 196: 111409. DOI: 10.1016/j.tws.2023.111409.Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J]. Advanced Engineering Materials, 2004, 6(5): 299-303. DOI: 10.1002/adem.20030 0567.Microstructure and wear property of WMoTaNb refractory high entropy alloy coating by laser cladding

[J]. Journal of Materials Research and Technology, 2024, 28: 1557-1569. DOI: 10.1016/j.jmrt.2023.12.082.Novel eutectic high-entropy alloy surfacing of flower-pot structure with outstanding wear resistance manufactured by laser cladding

[J]. Surfaces and Interfaces, 2023, 40: 103068. DOI: 10.1016/j.surfin.2023.103068.Effect of high-speed laser cladding on microstructure and corrosion resistance of CoCrFeNiMo0.2 high-entropy alloy

[J]. Journal of Central South University, 2022, 29(10): 3436-3446. DOI: 10.1007/s11771-022-5162-y.Microstructure and wear resistance property of AlFeCrNiMox coatings by plasma cladding

[J]. Materials Research Express, 2019, 6(10): 106537. DOI: 10.1088/2053-1591/ab3753.High temperature electrical properties and oxidation resistance of V-Nb-Mo-Ta-W high entropy alloy thin films

[J]. Surface and Coatings Technology, 2019, 375: 854-863. DOI: 10.1016/j.surfcoat.2019.07.080.Study on tribological oxide mechanism of CoCrFeNiMo high entropy alloy

[J]. Wear, 2023, 526-527: 204907. DOI: 10.1016/j.wear.2023.204907.Strengthening FCC-CoCrFeMnNi high entropy alloys by Mo addition

[J]. Journal of Materials Science & Technology, 2019, 35(4): 578-583. DOI: 10.1016/j.jmst.2018.10.009.Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases

[J]. Acta Materialia, 2016, 116: 332-342. DOI:10.1016/j.actamat.2016.06.063Microstructure and mechanical properties of multiprincipal component CoCrFeNiMox alloys

[J]. Materials Characterization, 2012, 70: 63-67. DOI: 10.1016/j.matchar.2012.05.005.New studies on wear and corrosion behavior of laser cladding FeNiCoCrMox high entropy alloy coating: The role of Mo

[J]. International Journal of Refractory Metals and Hard Materials, 2022, 102: 105721. DOI: 10.1016/j.ijrmhm.2021.105721.Evolution in microstructure, wear, corrosion, and tribocorrosion behavior of Mo-containing high-entropy alloy coatings fabricated by laser cladding

[J]. Corrosion Science, 2021, 191: 109727. DOI: 10.1016/j.corsci.2021.109727.A comparative study of the structure and wear resistance of NiCrBSi/50 wt.% WC composite coatings by laser cladding and laser induction hybrid cladding

[J]. International Journal of Refractory Metals & Hard Materials, 2016, 60: 17-27. DOI: 10.1016/j.ijrmhm.2016.06.019.Influence of Al2O3 particles on the tribological properties of CoCrAlYTa coating produced by laser-induction hybrid cladding

[J]. Ceramics International, 2021, 47(14): 19434-19442. DOI: 10.1016/j.ceramint.2021.03.280.Mechanical properties and formation mechanism of Ti/SiC system gradient materials fabricated by in-situ reaction laser cladding

[J]. Ceramics International, 2017, 43(1): 961-967. DOI: 10.1016/j.ceramint.2016.10.026.Effect of B4C content and particle sizes on the laser cladded B4C/inconel 625 composite coatings: Process, microstructure and corrosion property

[J]. Journal of Materials Research and Technology, 2024, 30: 6278-6290. DOI: 10.1016/j.jmrt. 2024.05.053.Effect of WC particles with different shapes during plasma spray on the properties of Fe-based composites coatings

[J]. Materials Research Express, 2019, 6(11): 1165h7. DOI: 10.1088/2053-1591/ab52a3.Microstructures and mechanical properties of FeCoCrNi high entropy alloy/WC reinforcing particles composite coatings prepared by laser cladding and plasma cladding

[J]. International Journal of Refractory Metals and Hard Materials, 2019, 84: 105044. DOI: 10.1016/j.ijrmhm.2019.105044.Microstructure evolution and tribological behavior of laser cladded Al1.8CrCuFeNi2/WC composite coatings on Ti-6Al-4V

[J]. International Journal of Refractory Metals and Hard Materials, 2023, 114: 106254. DOI: 10.1016/j.ijrmhm. 2023.106254.Microstructural evolution, mechanical and corrosion behaviors of as-annealed CoCrFeNiMox (x=0, 0.2, 0.5, 0.8, 1) high entropy alloys

[J]. Journal of Alloys and Compounds, 2020, 820: 153273. DOI: 10.1016/j.jallcom.2019.153273.Additive manufacturing of CoCrFeNiMo eutectic high entropy alloy: Microstructure and mechanical properties

[J]. Journal of Alloys and Compounds, 2022, 913: 165239. DOI: 10.1016/j.jallcom.2022.165239.The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of co-based coatings by laser cladding

[J]. Journal of Materials Research and Technology, 2021, 15: 2405-2418. DOI: 10.1016/j.jmrt. 2021.09.073.Effect of strengthening particles on the dry sliding wear behavior of Al2O3-M7C3/Fe metal matrix composite coatings produced by laser cladding

[J]. Wear, 2015, 324-325: 36-44. DOI: 10.1016/j.wear.2014. 11.023.Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC

[J]. Wear, 2015, 324: 80-89. DOI: 10.1016/j.wear.2014.12.021.Laser cladding of MMC coatings on aluminium substrate: influence of composition and microstructure on mechanical properties

[J]. Wear, 2005, 258(11): 1745-1754. DOI: 10. 1016/j.wear.2004.12.010.Effect of WC content on microstructure and properties of CoCrFeNi HEA composite coating on 316L surface via laser cladding

[J]. Materials, 2023, 16(7): 2706. DOI: 10.3390/ma16072706.Microstructure evolution of Fe-based WC composite coating prepared by laser induction hybrid rapid cladding

[J]. Applied Surface Science, 2010, 256(24): 7395-7399. DOI: 10.1016/j.apsusc.2010. 05.079.Thermodynamic properties of the Co-W-C system

[J]. Metallurgical Transactions A, 1989, 20(5): 935-956. DOI: 10.1007/BF02651660.A revised thermodynamic description of the Co-W-C system

[J]. Journal of Phase Equilibria and Diffusion, 2005, 26(2) : 152-160. DOI: 10.1361/15477030522473.Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding

[J]. Surface and Coatings Technology, 2020, 385: 125326. DOI: 10.1016/j.surfcoat.2019.125326.Microstructure and corrosion property of TC4 coating with Al0.5CoCrFeNi high-entropy alloy interlayer by laser cladding

[J]. Surface and Coatings Technology, 2024, 476: 130190. DOI: 10.1016/j.surfcoat.2023.130190.A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends

[J]. Journal of Manufacturing Processes, 2022, 75: 375-414. DOI: 10.1016/j.jmapro.2021.12.033.Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys

[J]. Materials Science and Engineering A, 2012, 556: 170-174. DOI: 10.1016/j.msea.2012.06.075.Microstructural evolution and wear characteristics of laser-clad CoCrFeNiMn high-entropy alloy coatings incorporating tungsten carbide

[J]. Journal of Alloys and Compounds, 2024, 976: 173124. DOI: 10.1016/j.jallcom.2023.173124.Enhanced surface layers by laser cladding and ion sulfurization processing towards improved wear-resistance and self-lubrication performances

[J]. Applied Surface Science, 2020, 503: 144226. DOI: 10.1016/j.apsusc.2019.144226.WCp/Fe metal matrix composites produced by laser melt injection

[J]. Surface and Coatings Technology, 2008, 202(9): 1771-1777. DOI: 10.1016/j.surfcoat.2007.07.053.LASER melt-particle injection processing

[J]. Surface Engineering, 1985, 1(4): 263-272. DOI: 10.1179/sur.1985.1.4.263.Mechanisms of laser energy absorption and melting behavior during selective laser melting of titanium-matrix composite: role of ceramic addition

[J]. Journal of Physics D-Applied Physics, 2021, 54(11): 115103. DOI: 10.1088/1361-6463/abcdce.Evaluation and mechanisms on heat damage of WC particles in Ni60/WC composite coatings by laser induction hybrid cladding

[J]. International Journal of Refractory Metals & Hard Materials, 2017, 64: 234-241. DOI: 10.1016/j.ijrmhm.2016.11.001.Laser produced functionally graded tungsten carbide coatings on M2 high-speed tool steel

[J]. Materials Science and Engineering A, 2001, 302(1): 106-114. DOI: 10.1016/s0921-5093(00)01361-7.Rare earth metal induced modification of γ-M2C, γ-M6C, and γ-MC eutectics in as cast M2 high speed steel

[J]. Materials Science and Technology, 1999, 15(6): 621-626. DOI: 10.1179/026708399101506355.Microstructures and mechanical properties of an AlCoCrNiFe HEA/WC reinforcing particle composite coating prepared by laser cladding

[J]. Materials, 2022, 15(22): 8020. DOI: 10.3390/ma15228020.Mo20Nb20Co20Cr20(Ti8Al8Si4) refractory high-entropy alloy coatings fabricated by electron beam cladding: Microstructure and wear resistance

[J]. Intermetallics, 2022, 149: 107669. DOI: 10. 1016/j.intermet.2022.107669.The effect of hardness on the frictional behaviour of metals

[J]. Wear, 1982, 78(3): 297-304. DOI: 10.1016/0043-1648(82)90240-X.Influence of electrical discharge machining on sliding friction and wear of WC-Ni cemented carbide

[J]. Tribology International, 2010, 43(12): 2333-2344. DOI: 10.1016/j.triboint.2010.08.008.Principles of abrasive wear

[J]. Wear, 1974, 28(1): 69-88. DOI: 10.1016/0043-1648(74)90102-1.Effect of Ti addition on the sliding wear behavior of AlCrFeCoNi high-entropy alloy

[J]. Wear, 2020, 462: 203493. DOI: 10.1016/j.wear.2020.203493.Effect of ultrasonic surface rolling processing on wear properties of Cr12MoV steel

[J]. Materials Today Communications, 2022, 33: 104762. DOI: 10.1016/j.mtcomm.2022.104762.Comparative study on tribological properties of the sulfurizing layers on Fe, Ni and Co based laser cladding coatings

[J]. Tribology International, 2019: 36-49. DOI: 10.1016/j.triboint.2019.01.019.Bonding, structure, and properties of metal/ceramic interfaces: Part 1 chemical bonding, chemical reaction, and interfacial structure

[J]. International Materials Reviews, 1993, 38(5): 233-256. DOI: 10.1179/imr.1993. 38.5.233.In situ SEM study on tensile fractured behavior of Al/steel laser welding-brazing interface

[J]. Materials & Design, 2022, 224: 111320. DOI: 10.1016/j.matdes.2022.111320.Influence of Al additions in Zn-based filler metals on laser welding-brazing of Al/steel

[J]. Journal of Manufacturing Processes, 2018, 34: 251-263. DOI: 10.1016/j.jmapro.2018. 06.008.Toward understanding the fractured mechanism in laser welded-brazed Al/steel interface by in-situ SEM tensile observations

[J]. Journal of Materials Processing Technology, 2024, 325: 118294. DOI: 10.1016/j.jmatprotec.2024.118294.LIU Xing-yi, YANG Xiao, CHEN Zu-bin, GUO Chun-huan, LI Hai-xin, YANG Zhen-lin, DONG Tao, JIANG Feng-chun, and QIAO Zhu-hui declare that they have no conflict of interest.

LIU Xing-yi, YANG Xiao, CHEN Zu-bin, GUO Chun-huan, LI Hai-xin, YANG Zhen-lin, DONG Tao, JIANG Feng-chun, QIAO Zhu-hui. Microstructure and wear property of laser cladded WC particles reinforced CoCrFeNiMo composite coatings on Cr12MoV steel [J]. Journal of Central South University, 2025, 32(1): 49-70. DOI: https://doi.org/10.1007/s11771-025-5850-5.

刘兴毅,杨霄,陈祖斌等.Cr12MoV钢表面激光熔覆WC/CoCrFeNiMo复合涂层的显微组织与耐磨性能[J].中南大学学报(英文版),2025,32(1):49-70.